Since over a year I have been meaning to start building a pedal steel guitar. After some failed attempts at an all-pull changer I've settled on making a Steel with a Pull-Release changer which is the most reasonably doable as soon as I get some suitable pieces of Aluminum to make the actual changer. Nonetheless, I've decided to start by making a glued panel beech (18mm thick) body measuring 80x20x8.8cm with beech ply fingerboard

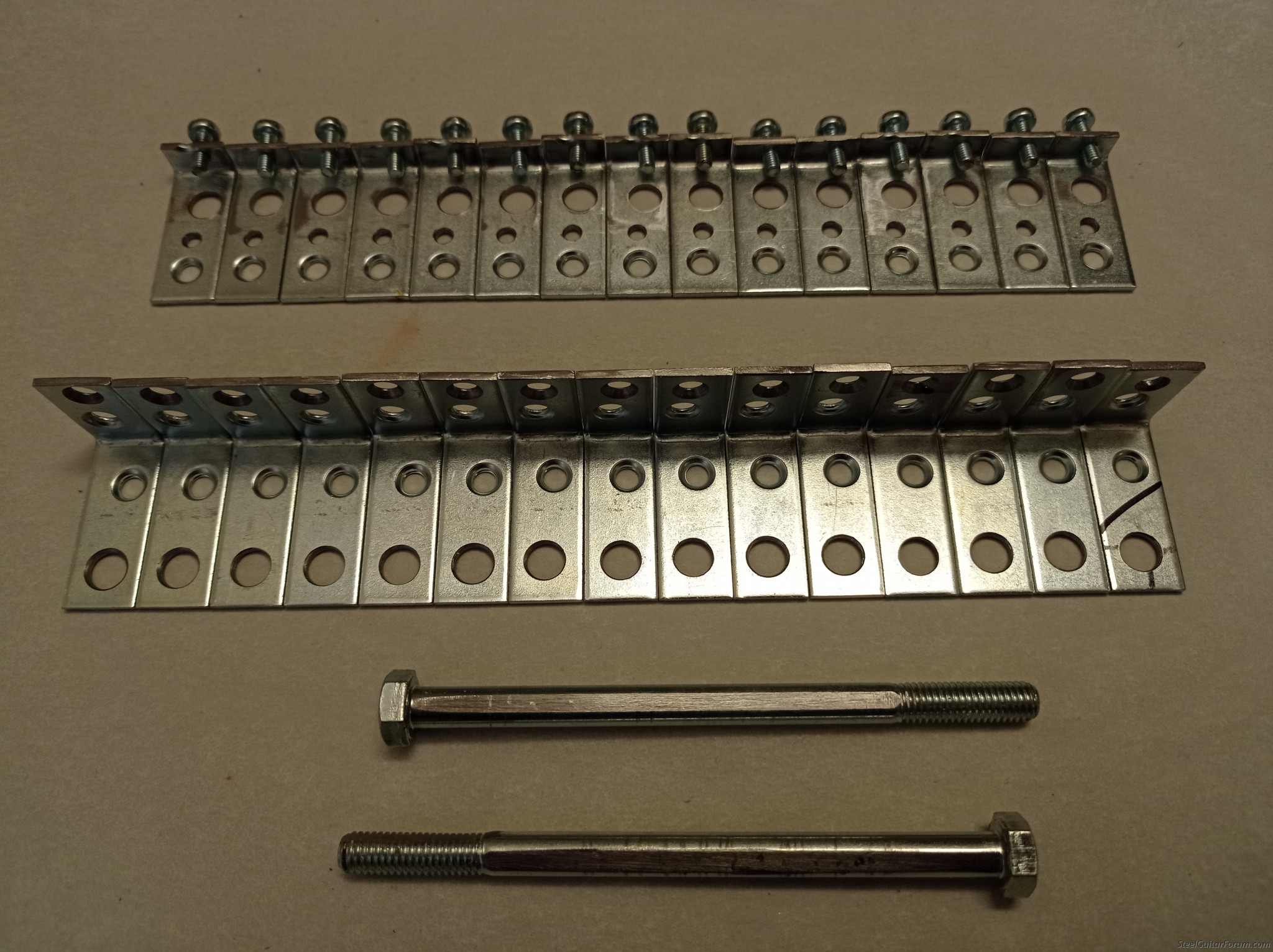

And making the most simple bell-cranks (pictured at the top) and holders for the cross bars (pictured at the bottom) from some 2mm thick galvanized steel corner pieces for chairs and using M8x120 bolts for the cross bars

The pull/release rods will be 3mm steel welding rods which turned out to be very easy to thread by hand

The tuning will be a 3x4 E9 10 string with Nashville tuning or a modification thereof. I will add to this during the coming months or so as I slowly progress. Feel free to correct me on my vocabulary

Cheers,

Javier Schulenburg