I still have some parts left over from the rare wood steel build and an old MSA D-10 guitar I would like to incorporate into this new build as all these parts are solidly made and would give a good basis for the guitar.

So depending on what wood is available to myself, the ideas are being discussed as the possibilities are endless. And with any of my builds, all using lacquer of coarse...

However before I start other than the wood, there are a few parts I still need, if anybody can help

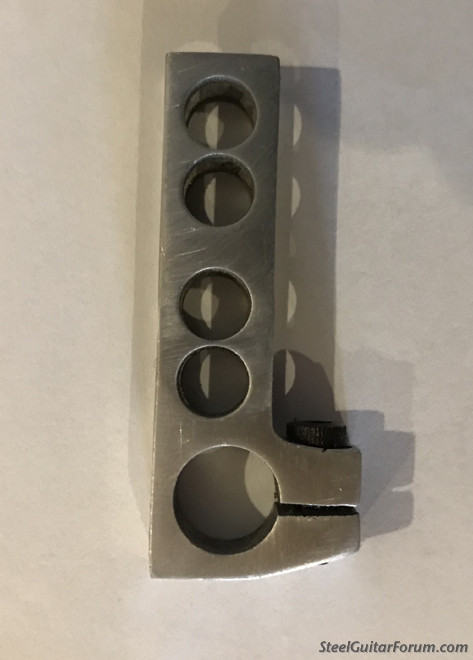

I need 6x MSA/Linkon 4 hole bell cranks/pullers. The old style with the 3/8 round shaft and locking screw.

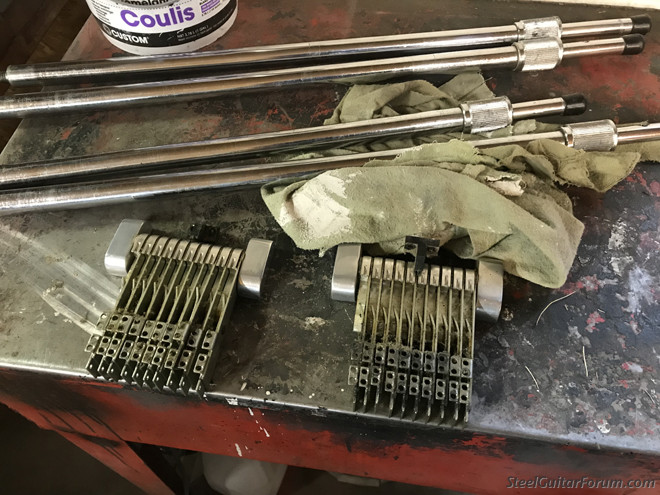

The rest of the parts I have found or had stashed away. I can buy them from you or I have some brand new Mullen bell cranks that have never been mounted. Six for a G2 or RP and a couple of older ones for a PRP plus all whats in the picture I could trade if anybody is interested.

thanks

Wayne