The neck pieces fit together perfectly, but when I laid them on the plywood there was a slight gap at the fretboard side, careful examination showed that the neck was slightly bowed. If I didn't know better, I would say that it was neck relief, the slight bowing in a regular guitar neck to compensate for the fact that the greatest amplitude of vibration of a string is at it's center. I suppose the bowing is caused by "creep," deformation caused by 60 years of string tension.

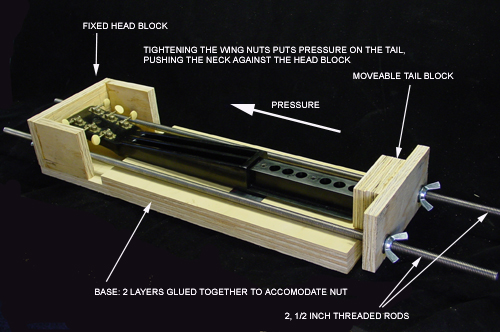

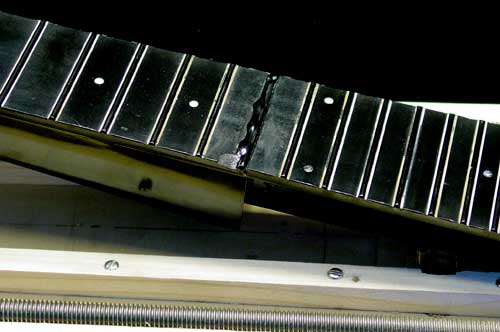

I discovered that if I held the peg head and pushed on the tail end of the neck, the pieces would line up perfectly. I built the gizmo with a loose piece at the tail end and two half-inch threaded rods with wing nuts to apply pressure.

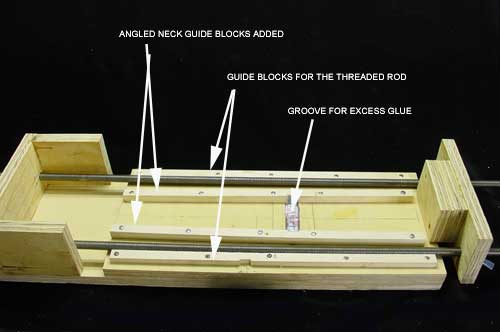

This worked fine except that the neck wasn't perfectly straight. I added two strips of wood on either side of the neck. the neck is a perfect taper from tail end of the fretboard to the nut, so pressure from the wing nuts would actually force it into alighnment. I also added to more strips of wood to keep the threaded rod in alignment. I made a groove underneath the joint and lined it with aluminum tape, so that any drips wouldn't glue the neck to the gizmo.

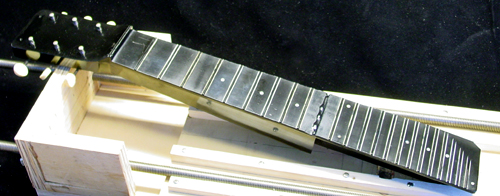

This worked fine so I mixed up the epoxy, which is mixed 4 to 1 epoxy to hardener. I have two matching sets of stainless steel measuring spoons, so I used one 1/4-teaspoon to scoop out 4 spoonfuls of epoxy resin and the other to measure out one 1/4-teaspoon of hardener. I poured them into a stainless steel measuring cup and stirred for 2 minutes. I then put in 2 drops of black colorant and contued stirring for 2 more minutes. I brushed it on both pieces with a throwaway brush, stuck them together and put the neck into the gizmo, and snugged up the wing nuts. I then turned the wing nuts until it was solid and hard to turn, but I didn't overdo it.

The instructions say that the epoxy reaches full strength after 2-1/2 days, so I left it in for 3 days.

I'll be able to sand down the excess to match the other frets. There is plenty of resin left to fill the low spots where chips popped out.

I strung it up this evening, it sounds wonderful!

Howie Clark<font size="1" color="#8e236b<font size="1" color="#8e236b<font size="1" color="#8e236b"><p align="center">[This message was edited by Howard Clark on 01 June 2005 at 11:57 PM.]</p></FONT>