Threading welding rod

Moderator: J D Sauser

- Tim Toberer

- Posts: 1048

- Joined: 23 Oct 2021 11:58 am

- Location: Nebraska, USA

Threading welding rod

Any tips for threading 3/32" or various sized of rod? How long should the threaded portion be? I did manage to put a 4-40 thread on the rod, about 1 3/16" long. It is not great, but it seems like it might work. I ground a little taper on the end that helped. The rod I am using is ER70S-2 Tig rod 3/32". I also thought about trying brazing rod which comes in this size.

-

Bobby D. Jones

- Posts: 2916

- Joined: 17 May 2010 9:27 am

- Location: West Virginia, USA

Have bought 3/32" 308L Stainless steel rod, At a local welding Shop, To make Pull Rods. MATHESON part no. MSS 308LT500MS. Cuts good, And produces smooth threads.

The taper on the rod to start die is a good idea.

Use oil on Die and Rod while cutting threads. Only turn die 1/2 turn (180 degrees) Then back up tap 1/4 turn (90 degrees) to break chips, So chips will come out of die. If chips pile up in the die it will tear the threads.

Most guitars only have 1/2" to 3/4" of the rod threaded. It is a good rule to not have rod threads dragging through the changer finger holes. Many guitar companies use a short sleeve of plastic or metal in front of the tuning nut, To make sure only smooth rod slides through the changer finger.

Be sure to use a new plastic tuning nut on the hand cut threads.

All factory pull rods I have worked with have Rolled Threads, Rolled threads are larger in diameter than die cut threads, And will make a loose fit of a used tuning nut.

I have not seen Bronze Brazing rods Smaller than 1/8", Made a couple quick fix rods for an old MSA out of them.

Good Luck in this project.

The taper on the rod to start die is a good idea.

Use oil on Die and Rod while cutting threads. Only turn die 1/2 turn (180 degrees) Then back up tap 1/4 turn (90 degrees) to break chips, So chips will come out of die. If chips pile up in the die it will tear the threads.

Most guitars only have 1/2" to 3/4" of the rod threaded. It is a good rule to not have rod threads dragging through the changer finger holes. Many guitar companies use a short sleeve of plastic or metal in front of the tuning nut, To make sure only smooth rod slides through the changer finger.

Be sure to use a new plastic tuning nut on the hand cut threads.

All factory pull rods I have worked with have Rolled Threads, Rolled threads are larger in diameter than die cut threads, And will make a loose fit of a used tuning nut.

I have not seen Bronze Brazing rods Smaller than 1/8", Made a couple quick fix rods for an old MSA out of them.

Good Luck in this project.

- Tim Toberer

- Posts: 1048

- Joined: 23 Oct 2021 11:58 am

- Location: Nebraska, USA

I was wondering about that.It is a good rule to not have rod threads dragging through the changer finger holes.

I have an old stash of flux coated brazing rods. I will double check but I am pretty sure they were 3/32". The flux is falling off so I figured I could possibly use them if I clean them up a bit. It is not something I would use if I didn't already have them.I have not seen Bronze Brazing rods Smaller than 1/8"

Thank You!Good Luck in this project.

-

Bobby D. Jones

- Posts: 2916

- Joined: 17 May 2010 9:27 am

- Location: West Virginia, USA

Check the flux covered rods, They may be 3/32".

I have dealt with flux covered rods that was smaller for a couple special jobs.

I did not want to suggest you buy flux covered rods, That are more expensive. And the rod would have to have the flux beat off them, And the rods polished with Steel wool before they could be used for pull rods.

I have dealt with flux covered rods that was smaller for a couple special jobs.

I did not want to suggest you buy flux covered rods, That are more expensive. And the rod would have to have the flux beat off them, And the rods polished with Steel wool before they could be used for pull rods.

-

Ted Duncan

- Posts: 101

- Joined: 20 Sep 2022 4:51 pm

- Location: Georgia, USA

Had you considered looking at McMaster-Carr? They have a very large selection of various rods in 3/32 in.

This is the page for 3/32": https://www.mcmaster.com/rods/diameter~3-32/ https://www.mcmaster.com/rods/diameter~3-32/

303 stainless might be what you are looking for.

This is the page for 3/32": https://www.mcmaster.com/rods/diameter~3-32/ https://www.mcmaster.com/rods/diameter~3-32/

303 stainless might be what you are looking for.

-

Larry Hobson

- Posts: 214

- Joined: 6 Feb 2017 9:29 am

- Location: Valley Grande (Selma) Al USA

Threading rods

Tim,. Saw this post and just had to reply. Many post have discussed this topic in the past. Do a search. Threaded rods are available. Having a rod already threaded only requires cutting to length and preparing the bell cranks end of the rod as required for your application. Recent rod purchases from Du-Bro Products inc. have been used by myself.part # 145-6 (30 in. 4-40 threaded rods) also part # 802 (12 in. 4-40 threaded end.) These rods are .092 diameter and have rolled threads with.106 diameter. Note ; part # 145-6 may be a quantity of 6 rods, not sure, one rod may be just #145. Good luck.

-

Larry Hobson

- Posts: 214

- Joined: 6 Feb 2017 9:29 am

- Location: Valley Grande (Selma) Al USA

- Jerry Overstreet

- Posts: 13910

- Joined: 11 Jul 2000 12:01 am

- Location: Louisville Ky

- Tim Toberer

- Posts: 1048

- Joined: 23 Oct 2021 11:58 am

- Location: Nebraska, USA

Yah I found a lot of those discussions. I went down the rabbit hole for hours and after that I still wasn't quite sure what I wanted to do. I guess this is a different ways to skin a cat situation. Now based on new advice, I am wondering if using a larger diameter might be better since this is a pull/release guitar.Saw this post and just had to reply. Many post have discussed this topic in the past. Do a search. Threaded rods are available.

Of course the other side of this question is how to make hex nylon tuning nuts. I bought some nylon electrical standoffs that I thought might work, but if I switch to 1/8" rod I think will need a larger size. I would prefer to just buy nylon hex rod, but had trouble finding it. If I remember correctly 1/8" rod take a 5-40 thread pretty well.? Thanks for all the comments, I am getting there.

-

Bobby D. Jones

- Posts: 2916

- Joined: 17 May 2010 9:27 am

- Location: West Virginia, USA

1/8" Pull rods works best if it is threaded 6-40.

6-40 gives a smoother/closer adjustment of pulls than the common 6-32 thread on rods.

Old Classic MSA's rods use 1/8" with 6-40 thread, And use a standard 3/16" Hex Plastic/Nylon tuning nuts with a 7/64" hole, The rod threads, Will cut threads in the plastic nut as installed.

5-40 is a little small for a 1/8" rod, Makes quite an offset at the Rod/Thread junction.

5-40 is the standard size for those odd size 7/64" rods, Used on Emmons Steels with E-clips to hold the pull rod in the Bell Crank.

Good Luck in this project, Happy Building.

6-40 gives a smoother/closer adjustment of pulls than the common 6-32 thread on rods.

Old Classic MSA's rods use 1/8" with 6-40 thread, And use a standard 3/16" Hex Plastic/Nylon tuning nuts with a 7/64" hole, The rod threads, Will cut threads in the plastic nut as installed.

5-40 is a little small for a 1/8" rod, Makes quite an offset at the Rod/Thread junction.

5-40 is the standard size for those odd size 7/64" rods, Used on Emmons Steels with E-clips to hold the pull rod in the Bell Crank.

Good Luck in this project, Happy Building.

- J D Sauser

- Moderator

- Posts: 3107

- Joined: 4 Aug 1998 11:00 pm

- Location: Wellington, Florida

- Contact:

McCarr have "easy to machine" 303 stainless rod in imperial and metric in a wide a range of diameters.

https://www.mcmaster.com/stainless-stee ... ess-steel/

I did some extra pull rods for my Excel which uses metric small diameter rods (much smaller than an MSA or Emmons) and could cut the thread with good lubrication using a hand tap perfectly.

I would not recommend using "welding rod".

... J-D.

https://www.mcmaster.com/stainless-stee ... ess-steel/

I did some extra pull rods for my Excel which uses metric small diameter rods (much smaller than an MSA or Emmons) and could cut the thread with good lubrication using a hand tap perfectly.

I would not recommend using "welding rod".

... J-D.

__________________________________________________________

Was it JFK who said: Ask Not What TAB Can Do For You - Rather Ask Yourself "What Would B.B. King Do?"

A Little Mental Health Warning:

Tablature KILLS SKILLS.

The uses of Tablature is addictive and has been linked to reduced musical fertility.

Those who produce Tablature did never use it.

I say it humorously, but I mean it.

Was it JFK who said: Ask Not What TAB Can Do For You - Rather Ask Yourself "What Would B.B. King Do?"

A Little Mental Health Warning:

Tablature KILLS SKILLS.

The uses of Tablature is addictive and has been linked to reduced musical fertility.

Those who produce Tablature did never use it.

I say it humorously, but I mean it.

- Tim Toberer

- Posts: 1048

- Joined: 23 Oct 2021 11:58 am

- Location: Nebraska, USA

This looks like the ideal material, but for this project I am trying to use only cheap available materials. It is really just a prototype proof of concept project. If I ever build another, I will be using only materials that will stand the test of time. Stainless welding rod seems like it would fit that bill as well. It may not take a thread as nice as the "easy to machine stuff" and probably not much cheaper. So I guess that should be taken into consideration. As far as the threading process goes, I will have to be a little more patient and clear the chips frequently. Hopefully that will make a nicer thread. My first attempt is pretty rough, but my tuning nuts do thread on ok. I am going to stick with 3/32" for now. I did find some people using that on their Marlen guitars so hopefully will work. Thanks again!McCarr have "easy to machine" 303 stainless rod in imperial and metric in a wide a range of diameters.

-

John Hyland

- Posts: 435

- Joined: 6 Sep 2021 10:45 pm

- Location: South Australia

I have just gone to a steel supply place a bought a 3 metre length of 1/8 “ mild steel rod for about $5Tim Toberer wrote:This looks like the ideal material, but for this project I am trying to use only cheap available materials. It is really just a prototype proof of concept project. If I ever build another, I will be using only materials that will stand the test of time. Stainless welding rod seems like it would fit that bill as well. It may not take a thread as nice as the "easy to machine stuff" and probably not much cheaper. So I guess that should be taken into consideration. As far as the threading process goes, I will have to be a little more patient and clear the chips frequently. Hopefully that will make a nicer thread. My first attempt is pretty rough, but my tuning nuts do thread on ok. I am going to stick with 3/32" for now. I did find some people using that on their Marlen guitars so hopefully will work. Thanks again!McCarr have "easy to machine" 303 stainless rod in imperial and metric in a wide a range of diameters.

Also little wastage as cut length exact to suit.

-

Bobby D. Jones

- Posts: 2916

- Joined: 17 May 2010 9:27 am

- Location: West Virginia, USA

If you order bulk rod material, Check the length and have it cut the 36"/1 Meter lengths. I ordered 48 ft of 7/64" stainless rod to make a set of Emmons E clip rods for a friend rebuilding a D-10 guitar. When the rod arrived at Fastenal there was 2 20' and 1 8' rods taped to a 20 foot wood 1"X3", The shipping was more than the rods cost.

The next time I ordered rod I had it cut 3 foot lengths and there was no extra charge on shipping.

The next time I ordered rod I had it cut 3 foot lengths and there was no extra charge on shipping.

- Larry Allen

- Posts: 1525

- Joined: 5 Apr 2004 12:01 am

- Location: Kapaa, Kauai,Hawaii

-

Bobby D. Jones

- Posts: 2916

- Joined: 17 May 2010 9:27 am

- Location: West Virginia, USA

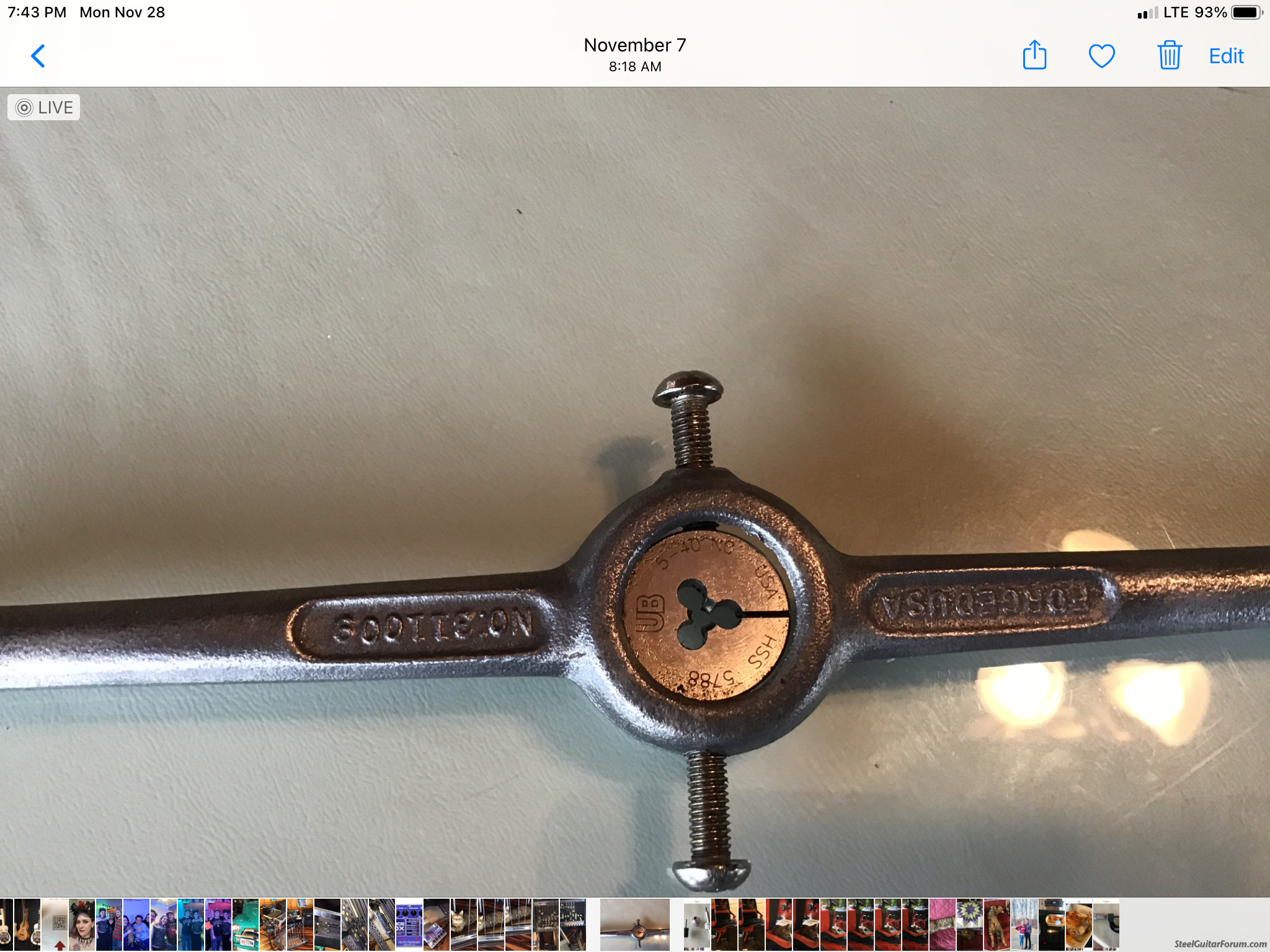

Adjustable dies, Like in the picture, Are the best dies to use when threading welding rod, Welding rod is made with some variance in size. The adjustable die allows a few thousands adjustment to level the threads with the shaft surface so the nylon tuning nuts will run smooth onto the rod shaft.

Every good machine shop I have been around, Have a set of adjustable dies to fit threads to threaded holes in the repair parts.

Every good machine shop I have been around, Have a set of adjustable dies to fit threads to threaded holes in the repair parts.