| Author |

Topic: A Better Sustaining Nut? |

Gary Spaeth

From:

Wisconsin, USA

|

Posted 30 Jun 2006 6:07 am

Posted 30 Jun 2006 6:07 am |

|

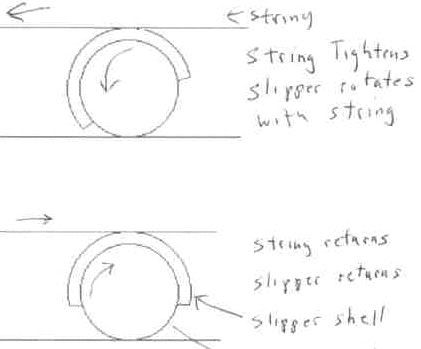

here's an idea for a roller nut for any psg. it would be just like a solid nut with the addition of these little snap on slipper shells. i think it would give much more contact with the body than conventional roller bridges. this might result in more sustain. also very cheap to manufacture. you could flatten the bottom of the shaft for more body contact. waddaya think?  [This message was edited by Gary Spaeth on 01 July 2006 at 09:58 PM.] |

|

|

|

Donny Hinson

From:

Glen Burnie, Md. U.S.A.

|

Posted 30 Jun 2006 1:06 pm

Posted 30 Jun 2006 1:06 pm |

|

| Gary, I think it's a great idea! It maintains the integrity of a collector steel, giving the option of returning to the "as-built" configuration at any time, while allowing a more reliable and more accurate tuning instrument. |

|

|

|

Jim Sliff

From:

Lawndale California, USA

|

Posted 30 Jun 2006 1:26 pm

Posted 30 Jun 2006 1:26 pm |

|

Actually, I think the rolling bridge is tremendous, but a rolling nut is not as essential. I've never seen a string break at the nut, and properly lubed a solid nut contributes to sustain and tone. In fact, I'd like to take my newer 400 and change the nut to a grooved bar instead of rollers!

The roller might do a little bit - but not as much as at the bridge end IMO, and I'm not sure the tonal tradeoff is worth it. |

|

|

|

Gary Spaeth

From:

Wisconsin, USA

|

Posted 1 Jul 2006 6:41 am

Posted 1 Jul 2006 6:41 am |

|

| i meant this as different nut design for all psgs, not just fenders or other vintage designs. i wonder if it would be an improvement over the standard roller nut on an emmons, carter, zum etc. in the sho-bud history page,Buddy Emmons said "...a keyhead without rollers gave sustain and tonal quality unmatched by any other guitar." this design would be as close as you could get to a solid nut with friction free roller bridge string movement. sring vibrations travel directly to the guitar body instead of indirectly down the roller nut shaft and then to the body. [This message was edited by Gary Spaeth on 01 July 2006 at 08:12 AM.] |

|

|

|

Donny Hinson

From:

Glen Burnie, Md. U.S.A.

|

Posted 1 Jul 2006 5:40 pm

Posted 1 Jul 2006 5:40 pm |

|

Gary, I think your idea is much more practical for the bridge than for the nut. As far as hurting the sustain of the old Fenders, I don't think that's a problem (they never had a lot of sustain to begin with). In fact, it's one of the hallmarks of their unique sound!

The myth that you need tons of sustain to play well and sound good is just that, a myth. |

|

|

|

ebb

From:

nj

|

Posted 1 Jul 2006 7:37 pm

Posted 1 Jul 2006 7:37 pm |

|

| amen |

|

|

|

Gary Spaeth

From:

Wisconsin, USA

|

Posted 1 Jul 2006 9:12 pm

Posted 1 Jul 2006 9:12 pm |

|

| i have edited my opening post because it gave the impression this thread is about fenders. donny, jim and ebb responded to this before i changed it so they responded correctly to the way i had originally framed it. sorry guys. |

|

|

|

John Bechtel

From:

Nashville, Tennessee, R.I.P.

|

Posted 5 Jul 2006 1:57 pm

Posted 5 Jul 2006 1:57 pm |

|

That l©©ks like a good idea to me!

------------------

“Big John”

a.k.a. {Keoni Nui}

Current Equipment

|

|

|

|

Peter Feller

From:

Palisades, New York, USA

|

Posted 5 Jul 2006 5:16 pm

Posted 5 Jul 2006 5:16 pm |

|

Gary,

The above design has a mechanical problem unrelated to sustain. That is, the ratio between the OD and the ID is too small to allow free spinning. In wheel and axle design, especially for journal bearings like a roller nut, the coefficient of rolling friction is made lowest when the ratio is made highest. For example, if the roller nut is, say, .375" in diameter, the best axle diameter would be the smallest shaft that would be practical from a mfg perspective. .125" diameter, or even smaller, sounds good to me. (3:1) I think the shaft/roller sleeve arrangment you drew, (4:3 ?) would offer too much resistance, and would interfere with returning to pitch. If I were designing a roller nut, I would make the ratio at least 5:1, or about a .500" roller on a .120" shaft. The steels I've seen are all in the 3:1 to 2.5:1 range. They work well, but I think they would work even better with a larger roller and a smaller shaft. |

|

|

|

Ron !

|

Posted 6 Jul 2006 3:27 am

Posted 6 Jul 2006 3:27 am |

|

Peter is right.The ratio is to small.I like the idea though.But lubracation is needed to make all this work.And what kind of lubracation are you going to use?Will it effect the sustain?

I worked on an idea a couple years ago that looked similar to this one.I wanted to do something like this at the changer side but never finished it.This Idea that you have here is a great one.

Ron

------------------

Click here to E-mail us.

Karen Kaylee Records

KRS D-10 10x8, KRS SD10 4x6 EMMONS P/P S10 3x5 Peavey Session 400 LTD, Peavey Ultra 15" Peavey All Tube 15"

Fender Twin Reverb Hilton Volumepedal

|

|

|

|

Gary Spaeth

From:

Wisconsin, USA

|

Posted 6 Jul 2006 7:00 am

Posted 6 Jul 2006 7:00 am |

|

| the drawing's not to scale. i made a prototype using this concept for a fender bridge and have been told it works well. the ratio is probably less than 4:3. i get the theory that longer moment arm exists in a larger diameter roller. you need less friction between the string and roller to overcome the friction of shaft and roller because of torque multiplication. right? [This message was edited by Gary Spaeth on 06 July 2006 at 06:52 PM.] |

|

|

|

Peter Feller

From:

Palisades, New York, USA

|

Posted 6 Jul 2006 6:08 pm

Posted 6 Jul 2006 6:08 pm |

|

Gary,

That's exactly right. The frictive load will be the same, but the higher ratio gives you a bigger mechanical advantage. Or, to invert that, it becomes easier for the bearing to affect the string's return. |

|

|

|

A. J. Schobert

From:

Cincinnati, Ohio,

|

Posted 6 Jul 2006 6:52 pm

Posted 6 Jul 2006 6:52 pm |

|

| I think viagra would be best to build a better sustaining nut. |

|

|

|

A. J. Schobert

From:

Cincinnati, Ohio,

|

Posted 6 Jul 2006 6:56 pm

Posted 6 Jul 2006 6:56 pm |

|

| good topic |

|

|

|

Gary Spaeth

From:

Wisconsin, USA

|

Posted 13 Jul 2006 2:04 pm

Posted 13 Jul 2006 2:04 pm |

|

| hey aj. a wife says to her husband, "i read in a health magazine that a tweny minute walk every day will improve your sex life." husband replies,"i don't know of any drug stores that close by." |

|

|

|

A. J. Schobert

From:

Cincinnati, Ohio,

|

Posted 13 Jul 2006 7:01 pm

Posted 13 Jul 2006 7:01 pm |

|

| Gary you are proof that not only does great cheese come from Wisconsin but also great American idea's, and I love the humor side as well. CARTER D10 |

|

|

|

Jim Sliff

From:

Lawndale California, USA

|

Posted 14 Jul 2006 12:23 pm

Posted 14 Jul 2006 12:23 pm |

|

"The above design has a mechanical problem unrelated to sustain. That is, the ratio between the OD and the ID is too small to allow free spinning."

Sorry, but your statements are not correct. I have the prototype of the bridge version installed on my 1000 as Gary's "guinea pig", and all 8 of them spin freely - in fact, that's the only downside....they move so nicely I have to secure them when changing strings!

It's a great idea that's been proven in an actual working unit. |

|

|

|

C. Christofferson

|

Posted 14 Jul 2006 1:03 pm

Posted 14 Jul 2006 1:03 pm |

|

It seems a positive idea, so my opinion of it is good.

I don't know if this has been mentioned recently or not but, there is the phenomenon of sympathetic type vibrations which will do the opposite of adding to sustain - that is 'cancel' or 'arrest' the strength of the origional vibration. So who can show that more vibration that makes it down into the body through the nut always helps. It's theoretically possible that it may deaden the tone at some frequencies ...my three cents worth.[This message was edited by C. Christofferson on 18 August 2006 at 03:02 PM.] |

|

|

|

Donny Hinson

From:

Glen Burnie, Md. U.S.A.

|

Posted 14 Jul 2006 2:14 pm

Posted 14 Jul 2006 2:14 pm |

|

| When comparing it with a regular nut/roller assembly, it has a much larger contact area, and that should translate into more friction. Unless some significant sonic benefits are evident, I don't see any advantage to incorporating it into a modern guitar. |

|

|

|