Figured I would ask here before contacting Gold Tone. Can anyone with one of these comment?

Moderator: Brad Bechtel

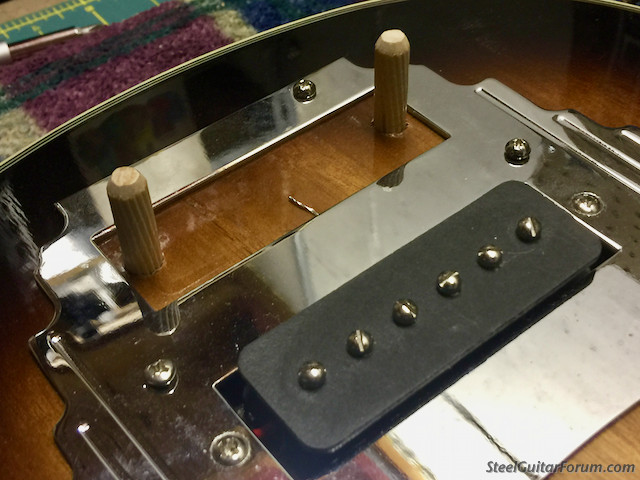

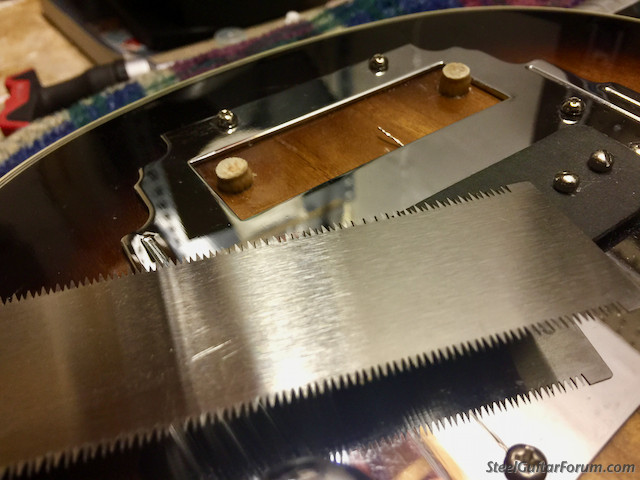

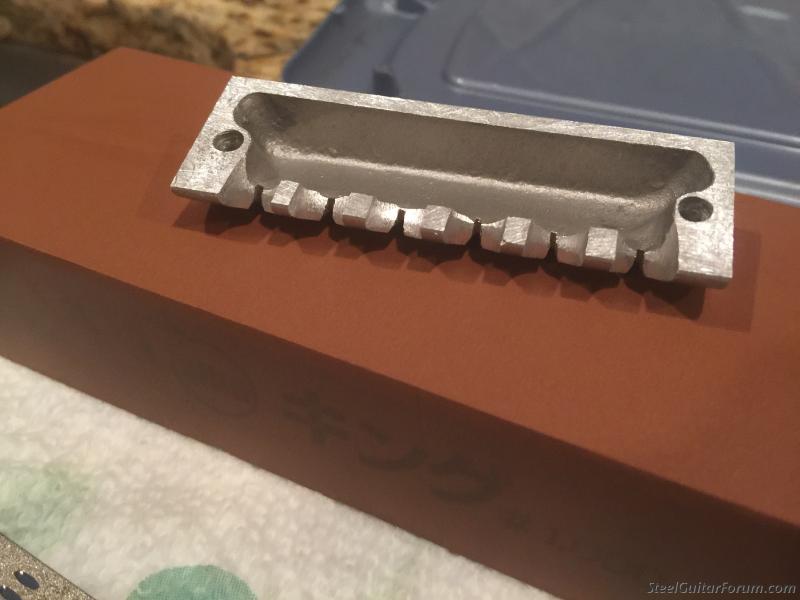

Justin - I had the identical problem with my Gold Tone LS-6, including the small wires in holes of the guitar for securing the bridge. I contacted Gold Tone and they repaired it for free because it was still under warrantee. The loose bridge problem is corrected and the LS-6 has a great sound, but stringing it is a chore because the strings do not lock correctly into the string slots on the bridge.Justin Lee wrote:Hoping someone can give me a reality check on how the bridge seems to be mounted on the new Gold Tone LS-6 I bought. It looks like the bridge is rolling forwards towards the neck instead of sitting flat against the body. I haven't tried adjusting the two bridge screws but the the bridge doesn't budge if I loosen the strings and try to rock it.

Figured I would ask here before contacting Gold Tone. Can anyone with one of these comment?