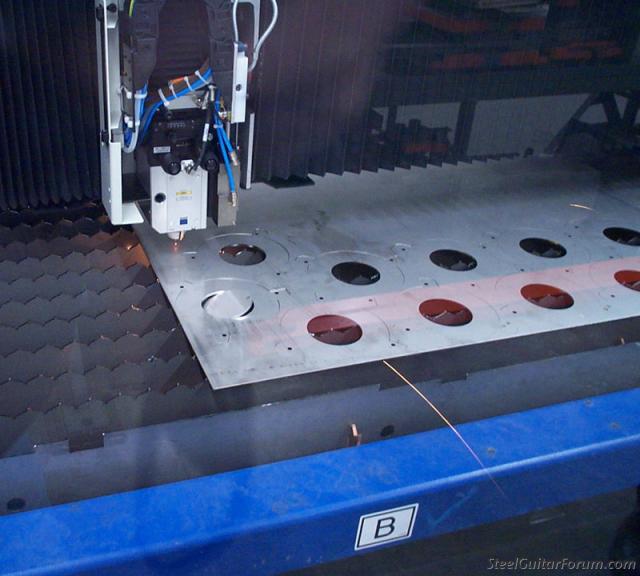

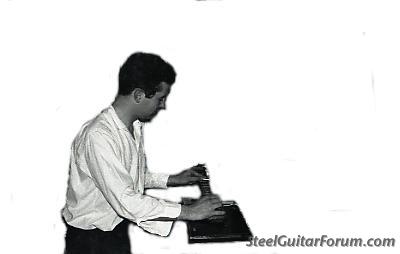

Move forward 46 years. Now I'm the CFO of a large manufacturing company in San Francisco. We have a multi-million-dollar laser machine that cuts steel like butter, to thousands-of-an-inch tolerance. I believe a lap steel can be made out of one piece of stainless steel, cut and bent appropriately. Over the weekend I'm going to make a mock-up in cardboard, which I shall hand over to one of our CAD engineers, and he will plot it on the computer in Solid Works, which he will feed into our Trumpf machine. Then the cutout will go to the Trumpf Press-Brake, where it will be bent to shape, and to the Welding Dept., who will weld the box closed.

As far as I know, no-one has ever built a lap steel out of steel before. I know that Fouke Industrial have built them from Aluminium. The laser machine will cut aluminum, but you have to clean it out afterwards before you start cutting steel again, which would be an expensive and time-consuming proposition.

I shall be giving a running commentary on progress. I'm excited to find out how it will sound. The President of the company is also excited about the prospect. He's a musician himself, and his daughter is a well-known singer and composer. If this goes well I have ideas for a resonator guitar with a steel body.