Page 1 of 4

My Lacquer Emmons Resto Phase 1

Posted: 25 Mar 2017 4:15 am

by Mike Scaggs

.

Posted: 25 Mar 2017 8:20 am

by Mike Scaggs

Emmons resto

Posted: 25 Mar 2017 8:24 am

by John Brock

Shazam!...thats a beauty...good luck on it..

Emmons PP

Posted: 25 Mar 2017 10:58 am

by Don Mogle

That looks great Mike! Keep the photos of the restoration coming. I love seeing this kind of stuff.

Don

Posted: 25 Mar 2017 11:31 am

by Herb Steiner

I kinda like the gold, Mike.

Posted: 25 Mar 2017 2:15 pm

by Abe Levy

Very cool!!

Posted: 25 Mar 2017 4:05 pm

by Mike Perlowin

Herb Steiner wrote:I kinda like the gold, Mike.

Me too. I think you should keep it. Especially if it goes well wth the wood stain you will be using.

Posted: 25 Mar 2017 4:23 pm

by Chris Lucker

What is going to happen to the fit of the rollers in the roller nut slots if the anodized surfaces are removed?

..

Posted: 26 Mar 2017 3:48 am

by Mike Scaggs

Hi Chris

Those rollers will fit just fine after the gold is removed as anodizing is almost like a stain and really has little if any thickness. That apparently was done after this guitar was made by lord knows who. In fact it buffs right off with not too much effort.

Posted: 26 Mar 2017 3:49 am

by Mike Scaggs

Herb Steiner wrote:I kinda like the gold, Mike.

Hate it LOL - besides, it all so rough in person I could never keep it on there. I think I'm going to do her up in a blue/black like this pic...

Posted: 26 Mar 2017 10:36 am

by Chris Lucker

Anodizing is not like s stain. A stain you could remove with a solvent and maintain material thickness. You are going to need to remove material to remove the anodizing. The buffing wheel you mention will not access the slots in the keyheads.

Count on 0.002" thickness of your gold anodizing in the surface of the Emmons alloy. The sanding or polishing belt will be removing 0.004" from each slot when you add both sides of each slot. Four thousandths is a lot of added slop. That is a piece of 7x tippet material.

Posted: 26 Mar 2017 8:03 pm

by Mike Scaggs

Chris Lucker wrote:Anodizing is not like s stain. A stain you could remove with a solvent and maintain material thickness. You are going to need to remove material to remove the anodizing. The buffing wheel you mention will not access the slots in the keyheads.

Count on 0.002" thickness of your gold anodizing in the surface of the Emmons alloy. The sanding or polishing belt will be removing 0.004" from each slot when you add both sides of each slot. Four thousandths is a lot of added slop. That is a piece of 7x tippet material.

Thank you for you insight Chis. You are obviously more skilled at this than I am. I guess stain was abad choice of words to describe the anodizing.

Posted: 26 Mar 2017 8:30 pm

by Chris Lucker

I have done it before, but have a lathe where I could machine the new rollers to fit.

.

Posted: 27 Mar 2017 2:29 am

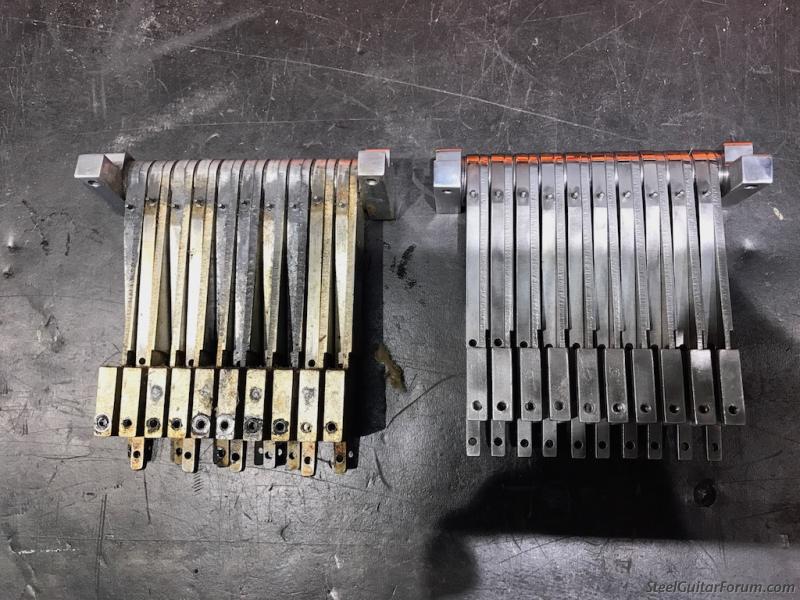

by Mike Scaggs

Posted: 27 Mar 2017 4:47 am

by Jeff Garden

Looks great, Mike! Those zip-loc bags look like a must to keep everything organized and not find extra parts after it's assembled

Two thumbs up for that blue and black color combination.

Posted: 27 Mar 2017 4:53 am

by Mike Scaggs

Jeff Garden wrote:Looks great, Mike! Those zip-loc bags look like a must to keep everything organized and not find extra parts after it's assembled

Two thumbs up for that blue and black color combination.

Thanks Jeff

Yeah I'm an amateur when it comes to this so the bags help me keep it all straight. My real thing is building/repairing tube amps which is of course dealing with lots of parts as well. Now it will be about 4 weeks before the body comes back (I hate waiting LOL)

Posted: 27 Mar 2017 9:16 am

by Henry Matthews

Wow Mike, you doing a great job, I liked the gold too.

That's going to be one nice guitar.

Southbound

Posted: 27 Mar 2017 9:18 am

by john widgren

Steve Fazio at Southbound did some work for me and I was very happy with the result. I went with poly and was glad I did.

Good luck..looks like a fun project... and when yer done:

OOH BABY!

Best, JW

Re: Southbound

Posted: 27 Mar 2017 9:28 am

by Mike Scaggs

john widgren wrote:Steve Fazio at Southbound did some work for me and I was very happy with the result. I went with poly and was glad I did.

Good luck..looks like a fun project... and when yer done:

OOH BABY!

Best, JW

Yeah ole Steve has quite the operation over there at Southbound. Just came from there and that smell! Love wood-shop smells. 4 weeks and waiting

Posted: 27 Mar 2017 9:46 am

by Herb Steiner

You're doing all the right stuff, man. The bags and the labeling are a must for OCD'ers. I use the same system when disassembling and reassembling. Makes things so much easier.

That will be one beautiful guitar when finished, Mike. Of this I am sure.

Posted: 27 Mar 2017 10:55 am

by Rick Johnson

That is a huge undertaking.

You got some skills....

Rick

www.rickjohnsoncabinets.com

Posted: 27 Mar 2017 12:02 pm

by Roger Rettig

That 'before' picture is scary - what on earth were they thinking?????

Posted: 27 Mar 2017 12:15 pm

by Tony Prior

great stuff, thanks for sharing !

Posted: 27 Mar 2017 5:49 pm

by Bobby Boggs

Looking good. The gold looked like nasty nicotine stain. As Roger wrote. What were they thinking.

Posted: 27 Mar 2017 6:00 pm

by Tony Glassman

Use the zip lock bags during rebuilds too.