Page 1 of 2

New 10 string Pedal steel Wide String Spacing.

Posted: 21 Mar 2015 2:21 pm

by Jimmie Hudson

I am looking to get feedback here on the forum on a new 10 string Pedal Steel Guitar with a 3/8 inch string spacing like some 6 and 8 string lap steels and some dobros have.

Would you share you opinion on whether you would like the wide 3/8 string spacing or would prefer the standard narrow spacing that is on most new 10 string pedal steels.

Thanks for your time and opinions.

I am thinking of coming out with a wide 3/8 string spacing Pedal steel is the reason for this poll.

Posted: 21 Mar 2015 3:32 pm

by Larry Phleger

I have always preferred the 3/8" spacing. I have never seen it used on a name brand steel, so I have learned to deal with the closer spacing that is standard on today's PSGs. If a pedal steel was built with a 3/8" spacing, the standard 10 string tone bars would be a little too short. I have built several non-pedal 10 steels using the 3/8" spacing and found the 12 string tone bar to be more appropriate for use with them.

tone bar

Posted: 21 Mar 2015 3:51 pm

by Jimmie Hudson

Larry Phleger wrote:I have always preferred the 3/8" spacing. I have never seen it used on a name brand steel, so I have learned to deal with the closer spacing that is standard on today's PSGs. If a pedal steel was built with a 3/8" spacing, the standard 10 string tone bars would be a little too short. I have built several non-pedal 10 steels using the 3/8" spacing and found the 12 string tone bar to be more appropriate for use with them.

The 12 string tone bar is very good for the 3/8 string spacing guitar. That is what I use with my guitar.

I also use a 12 string pickup to be sure to reach all the strings well.

Posted: 21 Mar 2015 4:00 pm

by Dave Zirbel

Those old Fender 10 stringers (models 800 and 2000) had 3/8" spacing. They feel great!

Posted: 21 Mar 2015 4:26 pm

by Roger Shackelton

I believe Buddy Emmons stated once in an interview that he would have liked to play a D-10 string PSG with 3/8 string spacing.??

Roger

Posted: 21 Mar 2015 4:55 pm

by Richard Wilhelm

If I was planning on buying another steel, that is what I would get. I don`t understand why it`s not done. I find the 3/8" to be just right on my Fender, and I have narrow fingers.

Posted: 22 Mar 2015 4:50 am

by Ian Rae

My home-built S12 has 3/8" spacing by accident and I don't care for it, having got used to the 11/32" spacing on my old D10. When I was making the changer, sloppy thinking had me drill and tap the rear crossbar for the split tuners at 3/8" centres, thinking that they would be a near enough approximation to the 9mm spacing I got from using metric steel stock for the fingers. But it wasn't, so I made some thin washers to increase it.

I want to make a new crossbar as soon as I have time.

11/32" = 8.73mm

3/8" = 9.53mm

so a little light sanding of the parts should achieve 11/32, although 9mm is probably a good compromise spacing anyway. (We live in a strange twilight zone over here where steel is metric but brass and aluminium are still in inches.)

Posted: 22 Mar 2015 5:55 am

by Charles Kurck

What many of us call spacing is actually the distance from center to center of the strings.

The distance between the strings is even less than the somewhat standard .34375” which is 11/32” at the changer.

Using common gauges of .036 and .038 on the E9th neck the distance between string 9 and 10 is only .30675 which is less than 5/16”.

With a tapered neck the area where we pick is even less than that.

It seems to me that it would be feasible to make a changer that shims could be added between the fingers to equalize the spacing between the strings.

Posted: 22 Mar 2015 7:19 am

by Jim Smith

Charles Kurck wrote:What many of us call spacing is actually the distance from center to center of the strings.

The distance between the strings is even less than the somewhat standard .34375†which is 11/32†at the changer.

Using common gauges of .036 and .038 on the E9th neck the distance between string 9 and 10 is only .30675 which is less than 5/16â€.

With a tapered neck the area where we pick is even less than that.

It seems to me that it would be feasible to make a changer that shims could be added between the fingers to equalize the spacing between the strings.

While your proposal "might" be possible, it certainly isn't practical. Center to center spacing has been standard forever. Who wants to re-shim their changer (and nut roller) every time you change string gauges and/or tuning?

Posted: 22 Mar 2015 8:16 am

by Ian Rae

Charles is correct in that what we call spacing should properly be called pitch - except in a musical context that would be confusing.

Posted: 22 Mar 2015 11:26 am

by Jamie Frost

I'm with Dave Z, I really like it. The Sho-Bud built Fenders have this spacing as well.

Posted: 23 Mar 2015 4:44 am

by Charles Kurck

Jim Smith:

I do not suggest shimming a guitar to match changing string gauges.

My changer idea would be to use shims so that all the fingers could be the same size

but the changer block would have progressively wider centers.

This would be a onetime factory setup using common string gauges as a reference.

For a changer with supports between each finger shims would not be needed

because the changer could have builtin wider centers for the bass strings.

Posted: 23 Mar 2015 8:05 pm

by Stephen Williams

My home built guitar has 3/8" spacing and I like it a lot. The normal steel spacing seems way too tight for me. What was the reason the spacing is so tight?

Posted: 23 Mar 2015 9:55 pm

by Jim Smith

Stephen Williams wrote:My home built guitar has 3/8" spacing and I like it a lot. The normal steel spacing seems way too tight for me. What was the reason the spacing is so tight?

I don't know for sure, but I always assumed that as more strings were added to the tuning, the spacing was reduced to help minimize the finger stretch between the top and bottom strings.

Posted: 24 Mar 2015 4:35 am

by Ian Rae

From the history I've read, mostly on this forum, the crucial change seems to have been from eight strings to ten.

Posted: 24 Mar 2015 8:27 am

by chris ivey

i don't think i could tell if strings were 1/32 inch closer or wider..i'm comfy with the emmons spacing.....which actually seems narrower than my old sho-bud professional.

Posted: 24 Mar 2015 10:24 am

by Lee Dassow

I wonder what the spacing is on the new Mullen.

I never thought to ask. T.L.

Posted: 24 Mar 2015 11:13 am

by Richard Wilhelm

It`s amazing what 1/32" makes. You`ll adding 9/32", less than 1/3" total string width to a 10 string guitar. But to me, it`s the difference between awkwardly tight and just perfect.

ttt

Posted: 26 Mar 2015 6:22 pm

by Jimmie Hudson

tttt

Posted: 26 Mar 2015 7:23 pm

by Don Chance

Having PSG string spacing more like a dobro would really nice.

Posted: 27 Mar 2015 3:16 am

by Ian Rae

Richard Wilhelm wrote:It's amazing what 1/32" makes.

I use four different trombone mouthpieces depending on which size of instrument I'm using. Their nominal inside diameters are 26.00mm, 25.73mm, 25.40mm, and 25.00mm.

The smallest increment is between the first two - works out at 0.011", a measurement we're all familiar with! The largest is still only 0.016". If I pick up the wrong one I know it as soon as I put it on my face - no need to blow. Why should not our fingers be just as sensitive?

[for reference, 1/32" = 0.031"]

Posted: 29 Mar 2015 3:10 pm

by Richard Wilhelm

This post is for Jimmy Hudson. If you do go ahead and build a new pedal steel, you might also think of terms of improving the scale length. I play a Fender long scale 400 in which you can easily change the bridge position. I also play in Eb9, this is because I feel I get better tone and it keeps from breaking the high G# string on the 24 1/2" scale with the solid bridge (a little bicycle chain grease also helps). Another player on the Fender Steel Forum recently decresed his scale length to 24 3/16", also to reduce string breakage. I

followed suite and did the same thing, but I came to 24 7/32". I did this not to keep from breaking strings which I had solved, but to give the strings more resonence and better pick attack. Now I tried 24 3/16" (6/32") but the tone went from perfectly round and focused to muddy and unfocused. That 1/32" absolutely made a world of difference. There's that same number again. Keep in mind that the early Fender guitars have pickups of around 10 ohm impedance compared to the modern steel pickup of around.of around 17 ohm. I don't know if that makes a difference but this is all food for thought. Good luck.

tuning

Posted: 30 Mar 2015 5:32 am

by Jimmie Hudson

Richard Wilhelm wrote:This post is for Jimmy Hudson. If you do go ahead and build a new pedal steel, you might also think of terms of improving the scale length. I play a Fender long scale 400 in which you can easily change the bridge position. I also play in Eb9, this is because I feel I get better tone and it keeps from breaking the high G# string on the 24 1/2" scale with the solid bridge (a little bicycle chain grease also helps). Another player on the Fender Steel Forum recently decresed his scale length to 24 3/16", also to reduce string breakage. I

followed suite and did the same thing, but I came to 24 7/32". I did this not to keep from breaking strings which I had solved, but to give the strings more resonence and better pick attack. Now I tried 24 3/16" (6/32") but the tone went from perfectly round and focused to muddy and unfocused. That 1/32" absolutely made a world of difference. There's that same number again. Keep in mind that the early Fender guitars have pickups of around 10 ohm impedance compared to the modern steel pickup of around.of around 17 ohm. I don't know if that makes a difference but this is all food for thought. Good luck.

I use a 24 inch scale and the pickups are in the 19 ohm range I have one of the guitars built. As soon as I get the photos I will post them. I like the 3/8 or .375 wide string spacing way better than the standard 10 string .312 to .340 spacing.

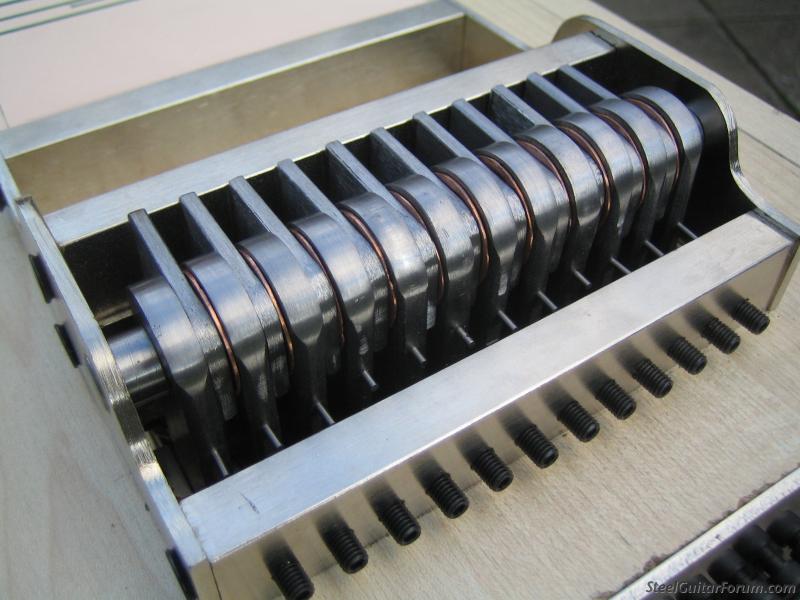

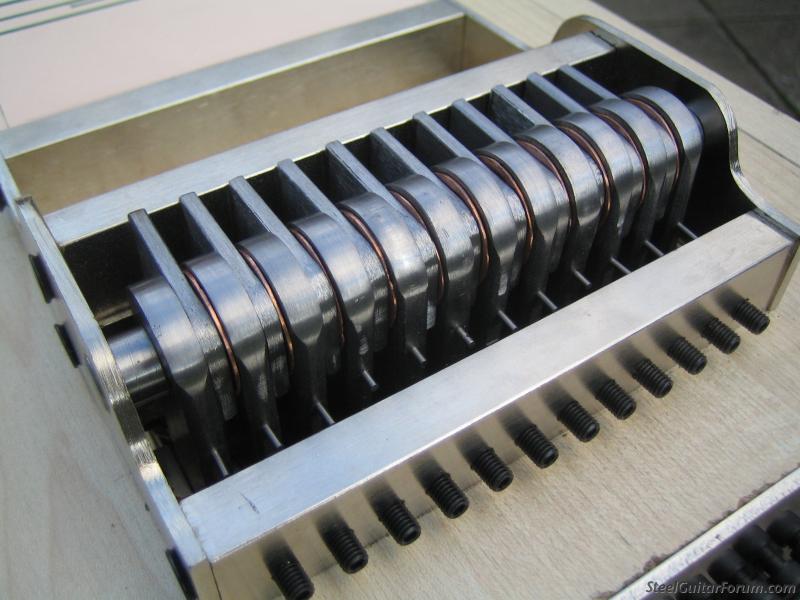

Photos of the Hudson 3/8 Wide string spacing guitar

Posted: 30 Mar 2015 10:38 pm

by Jimmie Hudson

The New Hudson 10 String 3/8 wide string spacing Pedal Steel guitar. Order your today.

Standard 3 floors and 4 knees, Pull Release Changer,

Real Maple Hardwood body neck and keyhead natural clear coat finish, Colors and stains Optional.

Standard E9th setup. Geoege L Eon Pickup is standard.

Base price starts at $995.00

Call for more information.

704-986-6481 8AM-9PM EST.

Posted: 8 May 2015 7:28 pm

by Roger Shackelton

Does anyone have a sketch of a pull release changer?

I find it difficult to imagine how this design works.

Roger