Page 1 of 2

Rhino Guard instead of using Tolex on an amp?

Posted: 29 Apr 2013 12:07 pm

by Jim Lindsey (Louisiana)

The Tolex on one of my Nashville 400s is crap now and totally peeling off. My nephew suggested sanding the wood down after getting the old Tolex off and spraying it with that Rhino Guard or Rhino Shield (like you'd spray into a truck bed as a liner).

I've never heard of covering an amp by spraying that stuff on the cabinet.

Anyone know if this would work as nicely as applying new Tolex? OR ... would it have a detrimental effect on the cabinet vibrations and alter the sound of the amp?

Posted: 29 Apr 2013 3:20 pm

by Steve Collins

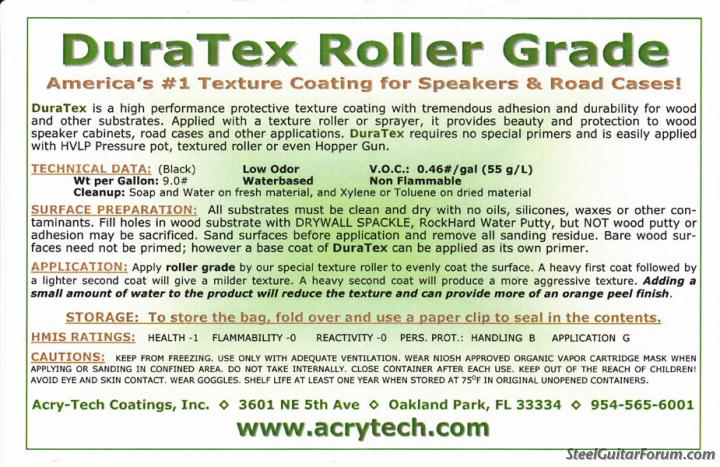

I built some cabs and used Duratex. It is water -based, really easy to apply with a roller, and you can control the amount of texture by which type of roller you use. I thought it gave really professional results.

http://store.acrytech.com/Speaker-Cabinet-Coatings/

Posted: 29 Apr 2013 3:34 pm

by Jim Lindsey (Louisiana)

Thanks, Steve!

I may have to check some of this stuff out.

Posted: 29 Apr 2013 3:39 pm

by Ken Fox

The glue Peavey used is animal glue and is water based. All you need is hot water and a large sponge to wet it good. Let it set a bit and use a wide scraper to get off the glue. Then wash good, let it dry and then fine sand it a bit. Done that many times to Peavey and Fender amps.

Posted: 29 Apr 2013 6:12 pm

by Jim Lindsey (Louisiana)

Thanks, Ken ... I'll follow your advice on that.

Posted: 30 Apr 2013 12:28 am

by Rich Hlaves

I have some Yamaha PA speakers that are factory covered with the bed liner stuff. They are several years old and wear like iron. I'd say give it a go.

Posted: 1 May 2013 8:10 am

by Darrell Birtcher

I rolled a couple of coats onto an SVT cabinet and it turned out great. It was too thick to get the corners back on though, so if I was to do it over again I'd spray a thin coat.

A friend had his keyboard amp done and he swears it made

it brighter and tighter sounding. He felt that the wood didn't resonate like it did before but he liked the sound better with the truck bed coating.

Posted: 1 May 2013 8:13 am

by Dale Rottacker

Posted: 1 May 2013 3:48 pm

by Paddy Long

I think the Telonics speaker cabinets have something similar to this ..a Urethane type finish -- it is very robust and hard wearing, far superior to Tolex thats for sure...

Posted: 1 May 2013 6:19 pm

by Jim Lindsey (Louisiana)

Thanks, guys. I just got the word from one of the Peavey guys that they're now using the Rhino (or similar) type stuff on new speaker cabinets (that is, if I heard him correctly).

I've also gotten a few emails from guys who've done the Rhino thing on their amp cabinets and they also stated it didn't change the sound of the amp and is far more durable than Tolex. It certainly seems easier than recovering with Tolex!

I'm definitely game to give it a try for sure. I'll take some before photos and then after photos to show how it comes out.

By the way, I've decided to give this stuff a try ...

Speaker Cabinet Texture Coating Duratex Roller Grade Trial Size Kit - Black

It's $19.95 and is enough to do two 18"x12"x12" cabinets (with two full coats for each cabinet), so it should be more than enough to cover one Nashville 400 cabinet.

Posted: 2 May 2013 3:31 pm

by Tim Whitlock

What a great idea! I have recovered a couple of amps with tolex and it this would be way cheaper and easier. I wonder if they make that stuff in vintage cream.

Posted: 2 May 2013 4:32 pm

by Buddy Castleberry

linex works better than the rino .i have used both. linex goes on hot and does a better job . they also did a lot of the yamaha speaker cabinets several years back

Beginning the project

Posted: 3 May 2013 5:30 am

by Jim Lindsey (Louisiana)

Here's a photo of the Nashville 400 cabinet freshly stripped of its old Tolex ...

Looks pretty rough, don't it? I was amazed how easy the old Tolex just pulled right off. It's almost as if the glue had lost all its adhesion to the Tolex, but not to the wood ... the boxtail joints on the top and bottom edges have places where I'm going to have to fill with wood-filler and smooth out in the sanding process before I coat it with the DuraTex.

I'm going to give an ever so slight light coat of flat black to the internal areas that were already painted black (just to cover the various spots that were not painted well when the amp was built). Also going to re-paint the black hardware that came off the amp.

Once the DuraTex gets here and I've coated the cabinet with it, I'll be intrigued to see just how durable it is and how well it holds up over time.

It's definitely going to be good to see my poor old amp reborn and not looking like it was run through a shredder ... the roadies weren't exactly careful with it when I was on the road.

Re: Beginning the project

Posted: 3 May 2013 8:48 am

by Tim Whitlock

Jim Lindsey wrote:I was amazed how easy the old Tolex just pulled right off.

Yep - stripping the old Tolex is the easy part. It usually peels right off. Cutting new Tolex to size, applying glue, positioning the sticky Tolex, fitting the corners, working the bubbles out - is a patience trying exercise. I'm looking forward to seeing the DuraTek finish.

Posted: 3 May 2013 6:03 pm

by Bruce Derr

Hmmm, I have to re-cover an S-10 case. I was going to use Tolex but maybe this stuff would be better and easier. I'll be interested to see how your amp project turns out.

Posted: 3 May 2013 7:02 pm

by Stephen Cowell

I've got JBL cabinets (MPro, SR series) that use this finish... it works great. Very tough and non-slippery.

Posted: 3 May 2013 7:58 pm

by Jim Lindsey (Louisiana)

I've got the cabinet all cleaned and sanded smooth, the interior of the cabinet freshly painted flat black. Also have the hardware with a fresh coat of black paint as well. All I'm waiting on now is the DuraTex to arrive so I can coat the cabinet. Will definitely post photos as soon as it's done.

For those who're interested in this project ...

Posted: 5 May 2013 5:57 am

by Jim Lindsey (Louisiana)

For those who're watching this topic to see how the project is going and ends up coming out, here's an update:

I just got the DuraTex kit this morning:

Not too much to it ... a roller, a bag of coating compound and a small page of directions (shown below):

According to the directions, I've already made my first mistake. When preparing the cabinet for the DuraTex, I used wood filler/putty for the holes. The directions say you can fill holes with drywall spackle or water putty "... but NOT wood putty or adhesion may be sacrificed."

Fortunately, the wood filler I used is paintable, so I've given the cabinet a good triple coat of flat black ...

As soon as the paint is completely dry the DuraTex should adhere to the painted surfaces where the wood filler had been used.

The directions say that a "heavy first coat followed by a lighter second coat will give a milder texture." They also say that a "heavy second coat will produce a more aggressive texture."

I'm going to opt for the milder texture so that it'll be easier to clean. I'll be posting more pictures later today as the project goes on.

To give the amp some "identity" from my other Nashville, I'm going to use a very dark hunter green for the metal hardware instead of the original black. This amp is my right stereo side amp (I have different amp settings on the right and left). When setting up I've had to look at my amp settings to identify the right amp from the left. Now, instead of having to rely on seeing the amp settings, it'll be right & left at a glance. The Nashville with black hardware will be the left, the Nashville with the dark hunter green hardware will be the right.

WOW! So easy to use!

Posted: 5 May 2013 10:51 am

by Jim Lindsey (Louisiana)

I have the first coat of DuraTex on the cabinet ...

First, I put the coating compound in a Glad container so I can keep it sealed (while not being used) and it's easy to also roll the little roller in as well:

Then I put on the first coat ... less than ten minutes to do and easy as can be ...

I'm impressed! This stuff really

does look like Tolex and I can't wait to see how it'll look after the second coat is on! Only thing is that the directions don't indicate how long to wait before adding the second coat. Just to be on the safe side, I'm going to give it a few hours before applying the second coat.

Photo of the second coat and then the finished project forthcoming.

Posted: 5 May 2013 1:45 pm

by Dale Rottacker

Jim, that cab looks really nice...I think you found the "goto" thing for bringing an older amp up to near new condition...Great Find!!!

Posted: 5 May 2013 2:19 pm

by Duke LeJeune

Very nice job Jim, and thanks for posting pics & descriptions of the process. I use Duratex in my business on a regular basis. You can also vary the texture by how much water you add to thin it, and if it's a hot/dry day, you may need to thin it anyway to give you adequate time to cover a whole side of the cab before it starts to get tacky.

If you do get a minor ding in the finish on your way to a gig, you can usually get away with using a black Sharpie for touch-up (smear it with your finger so it doesn't leave a shiny spot). And then the best part is, five minutes after you get home (plus drying time) and you can have the finish fully restored.

Posted: 5 May 2013 4:59 pm

by Lee Dassow

Damn Jim, Nice job, That looks great ! I'm gonna use that stuff on an Early 60's Ampeg B-15 bottom that I have. The original covering is all tore up.

Tennessee Lee

Posted: 5 May 2013 5:56 pm

by Jim Lindsey (Louisiana)

Thanks, guys.

I only just got home from going out for awhile and the sun is down, so I'll have to put the second coat on in the morning.

I'm eager to see how it'll look finished and all back together again.

Posted: 5 May 2013 6:05 pm

by Ransom Beers

I might use it to paint my bathroom & my truck & my park bench & my........

Jus' kiddin' Jimmy,looks good.I have an old Yamaha cab. ,I might do it to it!

Posted: 6 May 2013 6:40 am

by Tim Whitlock

That looks great! About 50% the cost of Tolex and glue and 100x easier. Will have to stick with Tolex for any vintage rebuilds, but this product will be a blessing for everyday cabinet builds/recovers. Thanks for sharing Jim - very helpful information!