Page 1 of 1

More Do-It-Yourself Cases - with a twist

Posted: 12 Mar 2008 6:52 am

by Darvin Willhoite

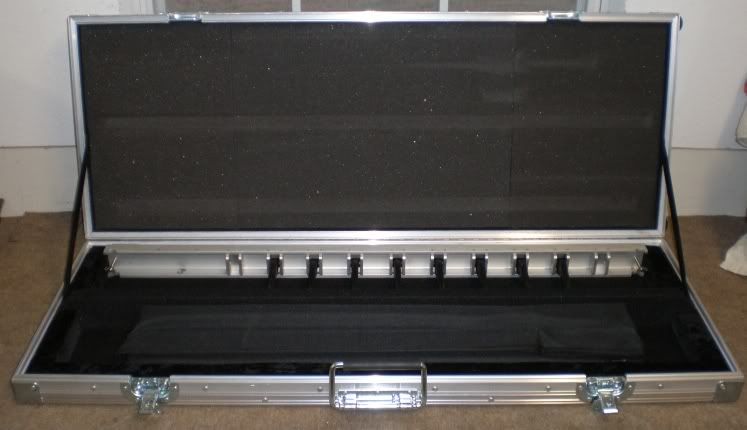

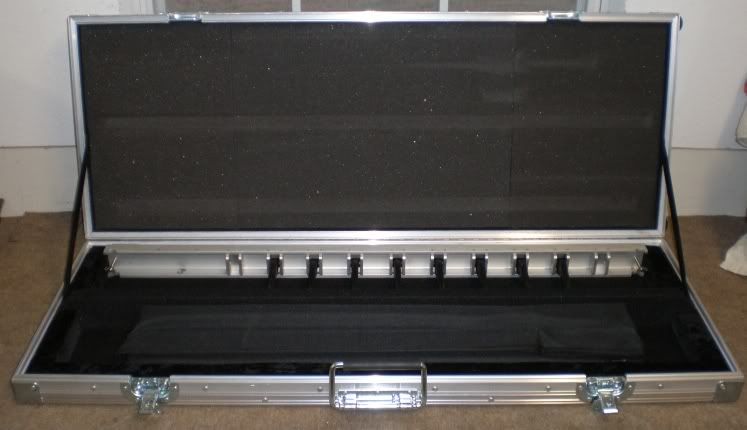

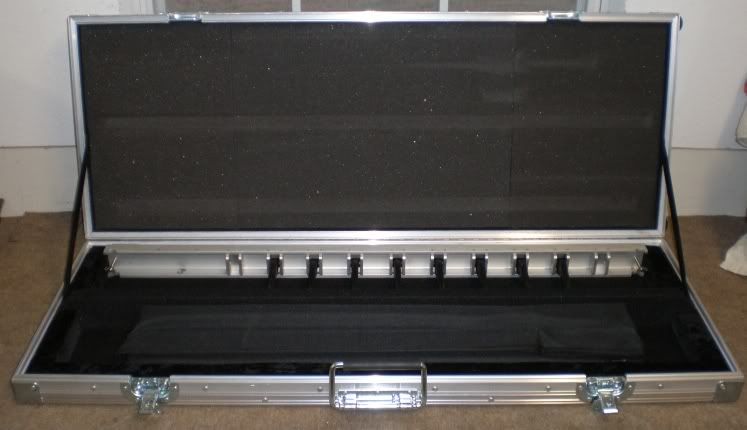

My old MSA Classic I just finished restoring had to have a new case, so I decided to do it myself, and do it a little different. A separate case for the pedal bar and legs for these older, heavier guitars is a must for us old guys, so I knew I wanted to go that route. I also love the wheeled cases that came with my new MSA's, so I decided to combine the two.

I used stacking type corners on the top of the main case and the bottom of the pedal bar case, then used a small butterfly latch on each end to hold the pedal bar case in place on the main case. This makes a single unit when you're using the wheels, but it detaches quickly and easily for loading and unloading, or setting up.

The guitar fits the case snugly and is surrounded by 1" foam (2" on the wheel end) covered with crushed velvet. The body is supported front and back in the center of the case, and also at the changer end. It does not sit on the tuning keys and changer. I put foam blocks in the lid to contact the end plates on both ends to keep the guitar tight in the case. This guitar ain't gonna move around in the case when it is handles in a sane manner.

The pedal bar case has foam in the lid to put pressure on the pedal bar and legs (in a leg bag of course), to keep them from moving around.

As you know, these old MSA's are pretty heavy, the main case with the guitar weighs 70 lbs, and empty, it weighs 28 lbs. The pedal bar case weighs 31 lbs. loaded, and 18 lbs. empty.

The materials probably cost me around $400, and I spent about 6 weeks in my limited spare time making them, but I am very pleased with the results. The snap-together design may be something some of you other players and case makers may want to take a look at.

Here's a bunch of pictures.

Posted: 12 Mar 2008 7:39 am

by Gary Cosden

Darvin - this is a good concept and a great job. Is that ABS/plywood laminate? If so, where did you source it? I have been thinking of building my own ATA type case to replace the one for my Sierra that at some point in it's life (I'm the third owner) took one hell of a hit. It did it's job and protected the guitar but cases are kind of like motorcycle helmets - one good hit and it's time to look for a new one.

Wow!!

Posted: 12 Mar 2008 7:50 am

by Dick Sexton

Darvin,

Very nice work. I like the locking piggy back idea and the added wheels. Careful, you'll be in the case business by sundown. DS

Posted: 12 Mar 2008 7:50 am

by Steve Norman

Man nice work ! pretty cool, I wonder if it would be possible to piggy back a 112 and a packa seat in something similar

Posted: 12 Mar 2008 9:37 am

by Greg Cutshaw

Darvin,

Very impressive work!

Greg

Posted: 12 Mar 2008 10:47 am

by Bill Ford

Nice work Bro Darvin.

Sorta reminds me of the old style MSA cases with the shelf for the legs/pedalboard, only outside.Just goes to show what you can do with a few tools,spare time & determination.

BF

Posted: 12 Mar 2008 11:02 am

by Bill A. Moore

Beautiful job, I have built this style case for equipment, but the normal rivits are a pain. It looks great using pop rivits. I think you've inspired me to build another case! Thanks, Bill. P.S., What did you use for backup for the rivits, just washers? Thanks again.

Posted: 13 Mar 2008 5:23 am

by Darvin Willhoite

Thanks for the comments guys, it was a lot of work, but it was worth it.

Gary, the material is ABS/plywood laminate. I bought the laminate and plywood separately and glued it together myself with contact cement. Reliable Hardware

http://www.reliablehardware.com/ or Case Ware

http://www.case-ware.com/info.html either one has the laminate. I think they also have pre-laminated material, but it would probably be really expensive, and shipping would be really high. Doug at Case Ware was really great to work with.

Bill, I didn't use backup washers for the rivets, but I did use grooved rivets that are made for use in wood. These are available from McMaster Carr company, and hold very well. I used an air rivet gun, there are about 300 rivets in both of these cases, I could not have done it with a hand rivet tool.

Steve, I'll bet you could piggyback about anything you wanted to. It would be a little tougher with the two items not being the same size, or same basic design, but there would be a way to do it. I kicked around several ideas for attaching the pedal board case and this was the simplest I came up with. I'm a design engineer by occupation, and I try to always use the KISS method. (Keep It Simple Stupid)

Posted: 13 Mar 2008 6:35 am

by Dale Hansen

Good work Darvin,

I've never seen it's equal anywhere.

It actually looks too nice to take out of the house.

Posted: 13 Mar 2008 7:19 am

by Darvin Willhoite

Thanks Dale, this was a lot of work for an old '74 MSA, but the guitar is virtually like new, so the cases may as well be nice too. I probably won't take it out once a year, but I can now take it out easily if I want to.

Here's the top side of the guitar.

Posted: 13 Mar 2008 7:37 am

by Dale Hansen

I meant every word Darvin, although brief.

I do really appreciate good craftsmanship, as a cabinet installer myself, and thats some very good work you've done there.

How long have you had the MSA? It looks like it was plucked right out of a 70's era catalogue, you've obviously taken great care of it.

Thanks for the info!

Posted: 13 Mar 2008 8:15 am

by Bill A. Moore

I live out here in the sticks, and had never even heard of the fasteners you used, thanks for the source info Darvin. That is a beautiful guitar also.

Posted: 13 Mar 2008 9:28 am

by Tommy Detamore

Awesome work Darvin! I used to build cases and I know how much work goes into it.....And the piggyback idea is great!

Posted: 13 Mar 2008 8:22 pm

by Darvin Willhoite

Dale, I have only owned this guitar about 6 months. It was in pretty good shape when I bought it, but I totally dis-assembled it, cleaned everything, had the end plates re-polished and put my setup ( 8 &

on it. I updated a few things too, like making the knee lever angle adjustable, and using my shaft stop design. I also put adjustable springs on the E9th neck to try them out, and they work great, so I'll be installing them on the C6th in the next week or so. I also had to raise it up 2". I am surprised at how good it plays and sounds, if it had been a dog, I sure would'nt have spent the time building the cases.

I'll do a post on the adjustable spring addition when I get them on both necks and play it a while that way.

Posted: 13 Mar 2008 8:23 pm

by Darvin Willhoite

double post

Posted: 14 Mar 2008 4:08 am

by Rick Johnson

Darvin

I know great work when I see it.

Those cases look super.

Rick

www.rickjohnsoncabs.com

Posted: 15 Mar 2008 5:53 pm

by Jim Bob Sedgwick

Kudo's Darvin.. Now that is craftmanship. I am so jealous. Makes the case I made look like a tinker toy set.

Posted: 16 Mar 2008 10:43 am

by Rick Hinton

Nice case!

Trans Continental Hardware (TCH) is also a good source for road case hardware, extrusion, ABS laminates, plywood, etc. I pick up all the hardware for my cases at the warehouse in Dallas (there are warehouses in Cleveland and Buffalo too), but you can order online through the web at

www.tchweb.com and they will ship it to you.

They have a great selection and usually contain the measurements in the picture/description.

Posted: 16 Mar 2008 11:04 am

by Curt Langston

Darvin, you have done an excellent job on those cases. Whats more, is the evidence that you live a blessed life. Some of the past pictures of your equipment reflect your exquisite and unique taste, with all of the various brands of top-of-the-line amps, guitars and equipment, all the way down to the parquet wood tiling in your very nice home. You always bring a positive light to the various threads, and never have I seen a post from you, condemning anyone. Seriously, you are a wonderful assest to the Forum, and I bet you are one heck of a nice guy.

Posted: 16 Mar 2008 7:52 pm

by Darvin Willhoite

Thanks for the nice words Curt, I have been extremely blessed. Most of this I'm sure, stemmed from my raising, which was right up the road from you in Claremore. I came to Texas in 1980, but I've still got a lot of Okie in me.

I always try to do the right thing, contribute time and money to the work of God, and things just seem to fall into place.