S12 Uni build project

Moderator: J D Sauser

- chris ivey

- Posts: 12703

- Joined: 8 Nov 1998 1:01 am

- Location: california (deceased)

When it's finished I shall cost it. If it turns out ok I shall build another one with a more conventional copedent and put it on Ebay to test the market for my vision of an affordable U12!

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

- Alan Brookes

- Posts: 13218

- Joined: 29 Mar 2006 1:01 am

- Location: Brummy living in Southern California

That's a good idea. After all, the biggest part of a project like yours is the planning. The second and subsequent machines become easier and easier. I guarantee that if you become well-known in Britain you will get orders, as there's not much competition, and US-built instruments are far too expensive to import.

But don't be surprised when customers start asking for a 10-string version for E9 tuning.

But don't be surprised when customers start asking for a 10-string version for E9 tuning.

[double post]

Last edited by Ian Rae on 29 Sep 2014 1:08 pm, edited 1 time in total.

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

- Alan Brookes

- Posts: 13218

- Joined: 29 Mar 2006 1:01 am

- Location: Brummy living in Southern California

-

James Quackenbush

- Posts: 2966

- Joined: 27 Sep 2002 12:01 am

- Location: Pomona, New York, USA

Ian,

Good Luck in your Uni venture .....I commend you for the work you are putting into this steel .....You mentioned working out a system for hopefully less 3rd string breakage ......In my experience with MANY Uni pedal steels , both keyed and keyless designs , the one major part of the equation that lends to most of the string breakage , is scale length !!......The longer the scale length , the more tension is put on the strings , and the 3rd string is wound so close to the breaking point on longer scaled steels ..... If you do a survey ( I have owned various Uni's ) you will soon see that the longer scale length steels are the ones most often with string break issues , especailly on the 3rd string .... Hope this helps ....Jim

Good Luck in your Uni venture .....I commend you for the work you are putting into this steel .....You mentioned working out a system for hopefully less 3rd string breakage ......In my experience with MANY Uni pedal steels , both keyed and keyless designs , the one major part of the equation that lends to most of the string breakage , is scale length !!......The longer the scale length , the more tension is put on the strings , and the 3rd string is wound so close to the breaking point on longer scaled steels ..... If you do a survey ( I have owned various Uni's ) you will soon see that the longer scale length steels are the ones most often with string break issues , especailly on the 3rd string .... Hope this helps ....Jim

Thanks for that, James. Mine is 24", the same as my existing instrument. I'm sure I've read somewhere that early Sho-Buds were 25" but they gave up and retreated to 24. Obviously some have stuck with it. I'm not sure what the attraction is. Tone and sustain are likely to be affected more by other parameters, although the longer scale will be slightly easier to play in tune.

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

- Alan Brookes

- Posts: 13218

- Joined: 29 Mar 2006 1:01 am

- Location: Brummy living in Southern California

-

James Quackenbush

- Posts: 2966

- Joined: 27 Sep 2002 12:01 am

- Location: Pomona, New York, USA

Actually the longer scale sustains a little bit better , and with the string tension increased , the "Flubby" sounding lower strings that you get with some UNI's due to the shorter scale .....Some manufacturer's get a tight sounding lower end with a shorter scale length , but I have found the longer scale lengths to have a much more punchy sound to them .....I like the feeling of the additional tension also ......More or less a sustain , and a feel thing .....However the longer scales as I mentioned earlier are NOTORIOUS for the 3rd string breaking due to the additional tension involved ..... Jim

PS ...You should have no issues with a 24" scale length .....Good Luck ....Jim

PS ...You should have no issues with a 24" scale length .....Good Luck ....Jim

Jim, I do see what you mean about the bottom strings, which really are bass guitar territory - you wouldn't normally build a bass that short. Alan, an inch is 4%, which is hard to ignore.

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

- Alan Brookes

- Posts: 13218

- Joined: 29 Mar 2006 1:01 am

- Location: Brummy living in Southern California

Logic says that if the scale length is one fret longer then the sting should be tuned a semitone lower. Keeping the same tuning and increasing the tension is like trying to tune a baritone guitar like a regular one.James Quackenbush wrote:...However the longer scales as I mentioned earlier are NOTORIOUS for the 3rd string breaking due to the additional tension involved ...

But if longer strings give better sustain, then why stop at 26"? Why not 36"?

ANYWAY...24" it is!

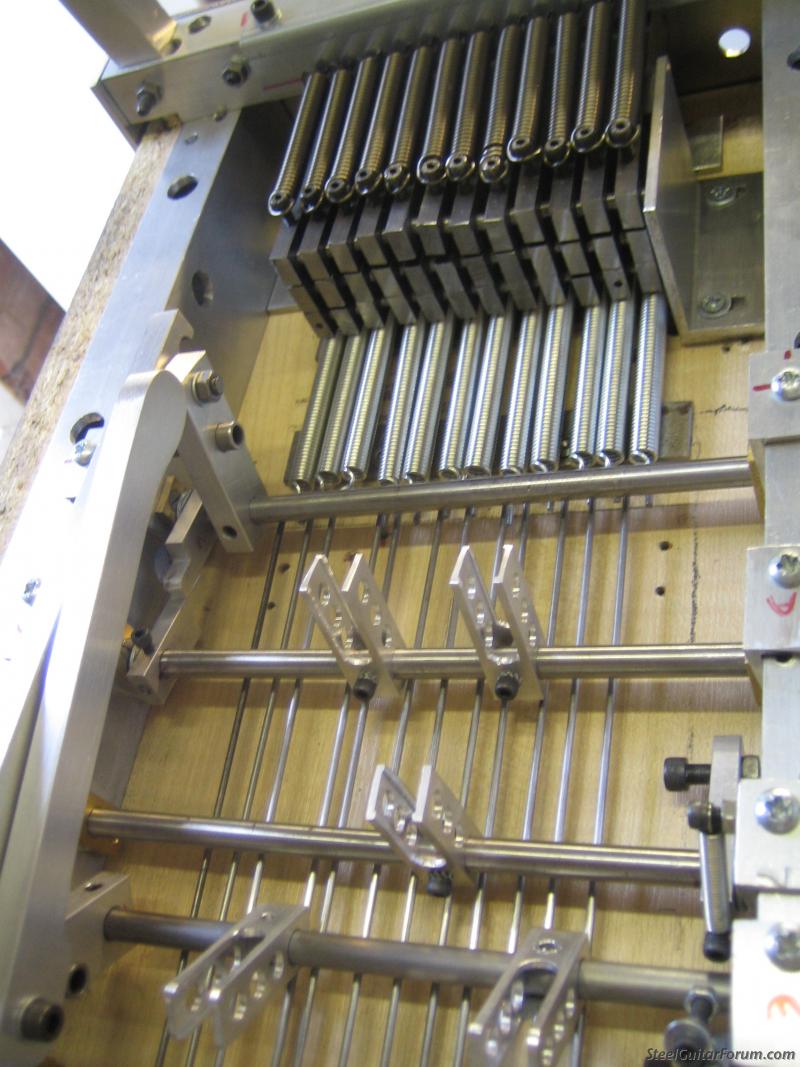

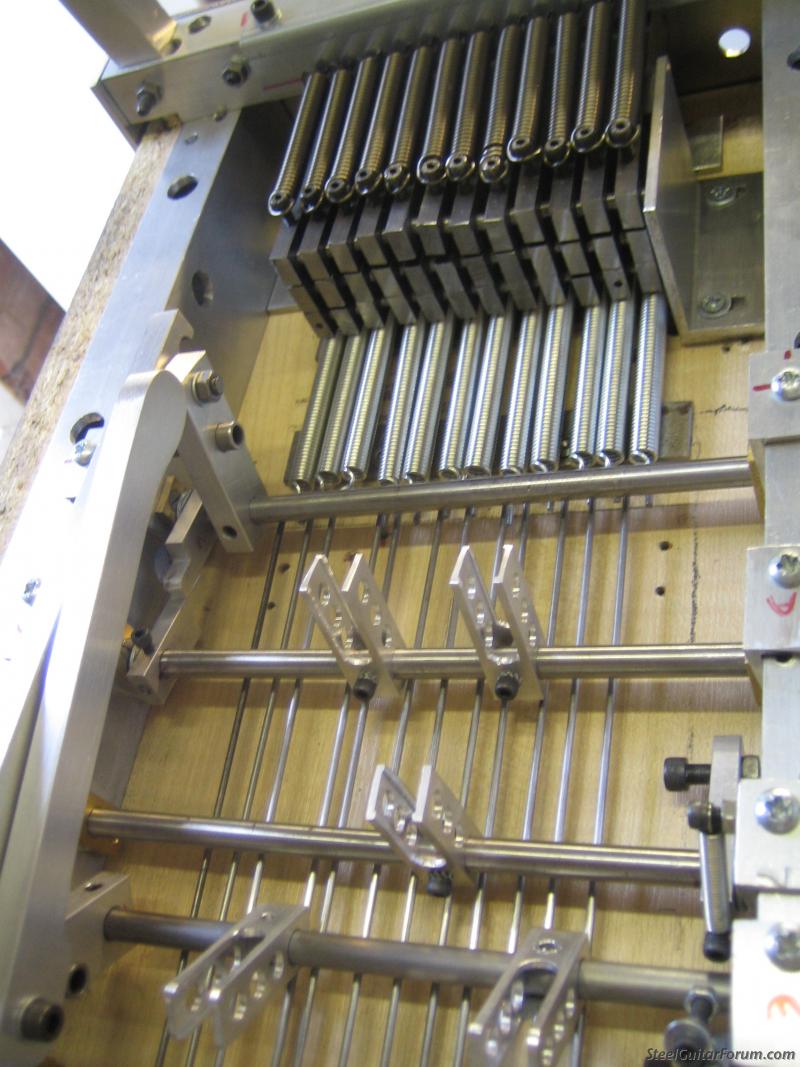

Here are all the pullers fitted to the cranks.

I decided that helper springs were going to be useful only if they were capable of fine adjustment. As there is no room at the changer end I've run wires up to the tuner endplate.

Seems like overkill, but could end up being useful.

Here are all the pullers fitted to the cranks.

I decided that helper springs were going to be useful only if they were capable of fine adjustment. As there is no room at the changer end I've run wires up to the tuner endplate.

Seems like overkill, but could end up being useful.

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

- Alan Brookes

- Posts: 13218

- Joined: 29 Mar 2006 1:01 am

- Location: Brummy living in Southern California

Amazing. All the parts are very durable and sturdy, I especially like the legs, which will give a much firmer foundation than most steels. It's made to last.

By the time I come over next year you'll have finished this, become proficient on it, and be in production, building for customers.

By the time I come over next year you'll have finished this, become proficient on it, and be in production, building for customers.

Last edited by Alan Brookes on 9 Oct 2014 3:56 pm, edited 1 time in total.

- Michael Maddex

- Posts: 1141

- Joined: 18 Apr 2007 5:02 pm

- Location: Northern New Mexico, USA

- Contact:

Ian, I find this to be very fine documentation of an excellent project. I especially like your one step at a time approach, starting with one string and one pedal and moving on from there. You are certainly learning some things that you couldn't learn any other way.

I have one major curiosity, though. I hope you will let us all know the total cost when you are finished. I expect that you will learn a lot (which is always a good thing) and wind up with a guitar meeting your particular requirements (another good thing), but I can't imagine that this project is going to cost less than a nice used guitar would. You may not count your time on this project (I know I might not on something similar), but I would be interested in hearing how many hours went into it as well as how much money.

Thanks for posting. I look forward to the ongoing saga.

I have one major curiosity, though. I hope you will let us all know the total cost when you are finished. I expect that you will learn a lot (which is always a good thing) and wind up with a guitar meeting your particular requirements (another good thing), but I can't imagine that this project is going to cost less than a nice used guitar would. You may not count your time on this project (I know I might not on something similar), but I would be interested in hearing how many hours went into it as well as how much money.

Thanks for posting. I look forward to the ongoing saga.

"For every expert, there is an equal and opposite expert." -- Arthur C. Clarke

- Geoff Noble

- Posts: 257

- Joined: 7 Feb 2012 12:30 pm

- Location: Scotland

Looking good Ian

What did you use for the legs, looks like aluminium square tubing?

I'm looking for a cheapish way to produce legs for a non-pedal steel I'm currently building, that looks like a cheap but solid way of producing them.

What did you use for the legs, looks like aluminium square tubing?

I'm looking for a cheapish way to produce legs for a non-pedal steel I'm currently building, that looks like a cheap but solid way of producing them.

"If it sounds good, it is good"

YouTube - http://www.youtube.com/channel/UCFqsA-A ... HGg/videos

Soundcloud - http://soundcloud.com/just-jef/tracks

YouTube - http://www.youtube.com/channel/UCFqsA-A ... HGg/videos

Soundcloud - http://soundcloud.com/just-jef/tracks

Michael, I share your curiosity! I intend to publish a costing when I'm done. I've pretty much finished spending money, but there's a little time to go.

What I do know in the meantime is that materials have cost around $700. When I took it into my head to try a uni I found that I live in a country where good used 12-stringers don't exist. I considered a non-working project but came up empty there too. I couldn't justify the cost of having one shipped from the States, so as I had the time I wondered if I could build one. My test was whether I could make a changer finger. This was my first effort that convinced me I could - everything else would be easy!

(I have also killed two birds by designing my tombstone.)

I've spent about 350 hours so far over the last 5 months, which equates to about 3½ hours a day. Most of it has been productive, because I've planned each step and generally not gone backwards. The planning time is not included (an hour or two an evening). My manufacturing of multiple parts has speeded up a lot. I should be able to make the next one in a couple of hundred hours.

That's assuming the one I'm on turns out ok! It won't have the factory finish you'd expect if you'd spent thousands, but if it works and sounds good I'll be happy.

Geoff, you're quite right - ¾" square x 10 gauge Ally box. The next one will have proper round screw-in legs but I wanted to get on with the mechanism. Should be good for what you want - strong and light.

What I do know in the meantime is that materials have cost around $700. When I took it into my head to try a uni I found that I live in a country where good used 12-stringers don't exist. I considered a non-working project but came up empty there too. I couldn't justify the cost of having one shipped from the States, so as I had the time I wondered if I could build one. My test was whether I could make a changer finger. This was my first effort that convinced me I could - everything else would be easy!

(I have also killed two birds by designing my tombstone.)

I've spent about 350 hours so far over the last 5 months, which equates to about 3½ hours a day. Most of it has been productive, because I've planned each step and generally not gone backwards. The planning time is not included (an hour or two an evening). My manufacturing of multiple parts has speeded up a lot. I should be able to make the next one in a couple of hundred hours.

That's assuming the one I'm on turns out ok! It won't have the factory finish you'd expect if you'd spent thousands, but if it works and sounds good I'll be happy.

Geoff, you're quite right - ¾" square x 10 gauge Ally box. The next one will have proper round screw-in legs but I wanted to get on with the mechanism. Should be good for what you want - strong and light.

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

- Geoff Noble

- Posts: 257

- Joined: 7 Feb 2012 12:30 pm

- Location: Scotland

Thanks Ian, might go for round instead of square but looks like a good way to go.

This song might go with your changer finger design, (except it would be a tombstone every 5mm)

https://www.youtube.com/watch?v=4aFzfDv2hz0

This song might go with your changer finger design, (except it would be a tombstone every 5mm)

https://www.youtube.com/watch?v=4aFzfDv2hz0

"If it sounds good, it is good"

YouTube - http://www.youtube.com/channel/UCFqsA-A ... HGg/videos

Soundcloud - http://soundcloud.com/just-jef/tracks

YouTube - http://www.youtube.com/channel/UCFqsA-A ... HGg/videos

Soundcloud - http://soundcloud.com/just-jef/tracks

- Alan Brookes

- Posts: 13218

- Joined: 29 Mar 2006 1:01 am

- Location: Brummy living in Southern California

The advantage of square is that it has flat surfaces, which are easier to drill into and much easier to join to other parts. One of the Achilles' Heels of a regular pedal rack is attaching a flat bar to a round leg. You end up with all sorts of compromises, mostly involving nut pressure to keep them in position, whereas with a bolt that goes through the leg, instead of just through some sort of retaining clip, you have much better stability. You can also fit hinges easily, so you can have legs that are hinged to the bottom of the guitar, which not only make for a quick setup, but prevent you from losing them or mixing them up, and the folded legs would protect the mechanism from damage during transit.Geoff Noble wrote:...might go for round instead of square but looks like a good way to go...

On the other hand, my old D10 [no longer] shown on the left has bolts through the round legs, and is rock solid. I think that if square-section legs were superior then they would have taken over by now. Same goes for folding ones. They would need some form of diagonal bracing which would add weight and look less than cool. They might protect the mechanism or damage it, and you'd lose the split-case option.

My current project has square legs only because I was eager to get on to the interesting part.

My current project has square legs only because I was eager to get on to the interesting part.

Last edited by Ian Rae on 6 Jun 2017 3:51 pm, edited 1 time in total.

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

- Geoff Noble

- Posts: 257

- Joined: 7 Feb 2012 12:30 pm

- Location: Scotland

Cheers for the advice guys. It'll be a while before I get to the legs, so plenty time to ponder before I commit!

I'd like to have the steel so that I can use it as a lap or mounted on legs, then comes the question do I want to play standing up or sitting down, so what length the legs? Making adjustable legs looks tricky so I may think about making the legs in two sections, removing one section takes it down from standing height to sitting height.

Anyway, don't mean to steal your thread Ian, I'm following this thread with a lot of interest. I must admit I was a bit curious about your approach to this when you first started, but it's proving to be a really interesting and innovative way to go about it.

Are you thinking about using stock pups or having a go at winding your own?

I'd like to have the steel so that I can use it as a lap or mounted on legs, then comes the question do I want to play standing up or sitting down, so what length the legs? Making adjustable legs looks tricky so I may think about making the legs in two sections, removing one section takes it down from standing height to sitting height.

Anyway, don't mean to steal your thread Ian, I'm following this thread with a lot of interest. I must admit I was a bit curious about your approach to this when you first started, but it's proving to be a really interesting and innovative way to go about it.

Are you thinking about using stock pups or having a go at winding your own?

"If it sounds good, it is good"

YouTube - http://www.youtube.com/channel/UCFqsA-A ... HGg/videos

Soundcloud - http://soundcloud.com/just-jef/tracks

YouTube - http://www.youtube.com/channel/UCFqsA-A ... HGg/videos

Soundcloud - http://soundcloud.com/just-jef/tracks

On this occasion I've bought a pickup. I ought to be able to make one, but when I look at what would be involved starting from scratch, suddenly an imported one looks really cheap! I prefer to busy myself with the mechanical stuff.

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

Pickup arrived, so I have all the strings on now.

The string pins are slightly random lengths as the fingers were not made all in one batch.

I'm pleased with the tuner as I only had the middle four strings on before and I wasn't sure how it would handle the thin and thick ones, but it's fine. It's reasonably easy to use, too. I'll write it up on a separate thread at some point. I need to refine my manufacturing to get a more even height on the fingers. The idea is to be able to slide seamlessly down to the zero fret, but I'm not sure I'm quite there yet.

I'm glad I went to the trouble of rigging up the helper-spring adjusters, as they've turned out to be pretty essential.

Now to start rodding it up!

The string pins are slightly random lengths as the fingers were not made all in one batch.

I'm pleased with the tuner as I only had the middle four strings on before and I wasn't sure how it would handle the thin and thick ones, but it's fine. It's reasonably easy to use, too. I'll write it up on a separate thread at some point. I need to refine my manufacturing to get a more even height on the fingers. The idea is to be able to slide seamlessly down to the zero fret, but I'm not sure I'm quite there yet.

I'm glad I went to the trouble of rigging up the helper-spring adjusters, as they've turned out to be pretty essential.

Now to start rodding it up!

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs

- Per Berner

- Posts: 1808

- Joined: 10 Aug 2004 12:01 am

- Location: Skövde, Sweden

- Contact: