Inexpensive source for pull rods?

Moderator: Shoshanah Marohn

- John Maggard

- Posts: 58

- Joined: 2 Jun 2005 12:01 am

- Location: Cincinnati Ohio, USA

Mike,

I've also purchased from this place that offers threaded rod and pipe:

http://images.google.com/imgres?imgurl= ... s%26sa%3DG

It only shows sizes down to 10-32, but offers custom work so who knows? You can also find most taps and dies individually or in small sets; I don't have anything other than metric here smaller than a 6-32 or I'd throw it in an envelope and mail it to you - sorry!

John

I've also purchased from this place that offers threaded rod and pipe:

http://images.google.com/imgres?imgurl= ... s%26sa%3DG

It only shows sizes down to 10-32, but offers custom work so who knows? You can also find most taps and dies individually or in small sets; I don't have anything other than metric here smaller than a 6-32 or I'd throw it in an envelope and mail it to you - sorry!

John

-

Dick Cochran

- Posts: 68

- Joined: 4 Aug 1998 11:00 pm

- Location: Conesville, OH USA

- Mike Wheeler

- Posts: 3058

- Joined: 18 Oct 2004 12:01 am

- Location: Delaware, Ohio, USA

-

Gabriel Stutz

- Posts: 379

- Joined: 18 May 2006 12:01 am

- Location: Chicago, USA

A welding store is the way to go. I went to one to get steel rods for the lowers on my push/pull and since I only need 2 the guy just gave them to me, which was great. Nice Dekley, by the way. I have a D10 that I absolutely love. I've wondered about making rods, but I don't know how to put the threads on the rod. Is it something I can do in my apartment, or do I need a machine shop?

Gabriel

Gabriel

- John Maggard

- Posts: 58

- Joined: 2 Jun 2005 12:01 am

- Location: Cincinnati Ohio, USA

Gabriel,

Threading the rod is easy by hand, although the rod will need to be firmly clamped in a vise or some other way.

A manual die (sized to the rod/thread size you desire) and die wrench plus some light machine oil will get it done.

On the other hand if you know someone with a shop

and the right tools it may be cheaper, faster & will be more precise.

John

Threading the rod is easy by hand, although the rod will need to be firmly clamped in a vise or some other way.

A manual die (sized to the rod/thread size you desire) and die wrench plus some light machine oil will get it done.

On the other hand if you know someone with a shop

and the right tools it may be cheaper, faster & will be more precise.

John

- Tom Mossburg

- Posts: 335

- Joined: 27 Sep 2006 12:01 am

- Location: AZ,

-

Gabriel Stutz

- Posts: 379

- Joined: 18 May 2006 12:01 am

- Location: Chicago, USA

- Tom Mossburg

- Posts: 335

- Joined: 27 Sep 2006 12:01 am

- Location: AZ,

- Mike Wheeler

- Posts: 3058

- Joined: 18 Oct 2004 12:01 am

- Location: Delaware, Ohio, USA

Tom, what rod size did the 6-32 relate to? It seems to me it would be really close to 1/8th. And I seem to remember someone saying that the smaller thread-per-inch made for better fine tuning.

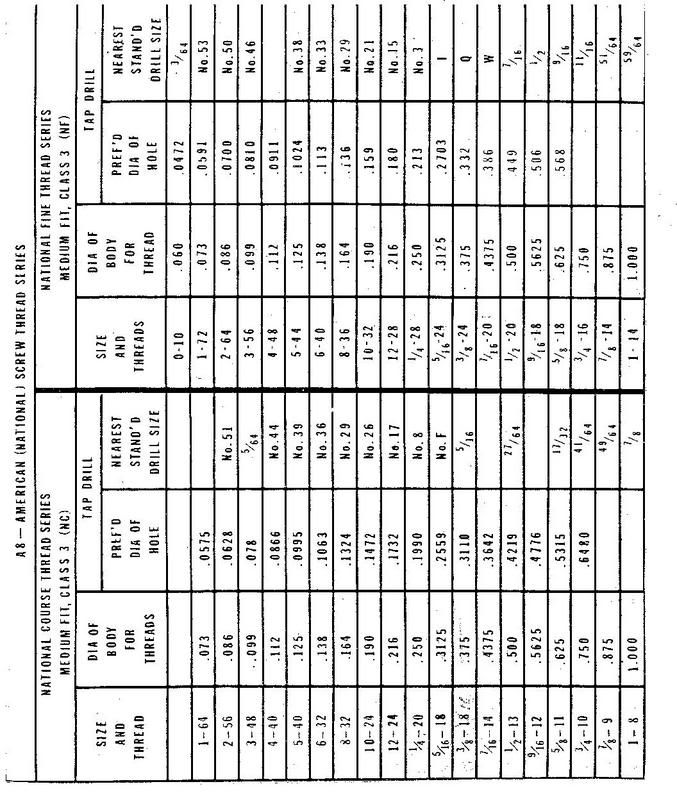

Sure would like to find a chart like that...would clear up some mystery. ha! Any machinists out there have a web site to recommend?

Sure would like to find a chart like that...would clear up some mystery. ha! Any machinists out there have a web site to recommend?

Best regards,

Mike

Mike

-

Donny Hinson

- Posts: 21192

- Joined: 16 Feb 1999 1:01 am

- Location: Glen Burnie, Md. U.S.A.

MSA rods...

MSA rods are 1/8" (.125), and thread size is 5-40. You can do a 6-32 thread on 1/8" rod, but it will be a very crappy (loose and rough) thread.

- Mike Wheeler

- Posts: 3058

- Joined: 18 Oct 2004 12:01 am

- Location: Delaware, Ohio, USA

- Erv Niehaus

- Posts: 26797

- Joined: 10 Aug 2001 12:01 am

- Location: Litchfield, MN, USA

-

Donny Hinson

- Posts: 21192

- Joined: 16 Feb 1999 1:01 am

- Location: Glen Burnie, Md. U.S.A.

Rod size...

Mike, for 6-32 thread you can use 9/64" rod, which measures .1406". That a couple thousandths over the #6 major thread diameter, but as close to a "standard size" as you can get.

Tom, 3-48 is a very rare size. I don't know of any steel manufacturers that use it. Emmons uses 7/64" rod, and they thread it 4-40. That's only a couple of thou off, so it works pretty well.

Erv, probably the only reason that you're having success with 1/8" rod threaded to 6-32 is that you're using standard nylon tuning nuts, which are usually unthreaded when new. If you put a standard (metal) 6-32 nut on that rod, you'll see immediately notice how sloppy the fit is.

Tom, 3-48 is a very rare size. I don't know of any steel manufacturers that use it. Emmons uses 7/64" rod, and they thread it 4-40. That's only a couple of thou off, so it works pretty well.

Erv, probably the only reason that you're having success with 1/8" rod threaded to 6-32 is that you're using standard nylon tuning nuts, which are usually unthreaded when new. If you put a standard (metal) 6-32 nut on that rod, you'll see immediately notice how sloppy the fit is.

- Tom Mossburg

- Posts: 335

- Joined: 27 Sep 2006 12:01 am

- Location: AZ,

Thread Sizes

Here's what I've got. I'll try to post the whole chart or e-mail it to anybody who wants it. First is the thread size then the Diameter of the body for threads. 3-48 .099, 4-40 .112,5-40 .125, 6-32 .138. I picked up both the 3-48 and 5-40 dies at Marshall tool here in Phoenix. You can get them fro McMaster-Carr also. The 3-48 is just right for 3/32 rod. I've run into a dead end on the 7/64 rod as that is not a standart TIG welding rod size. Anybody have a source?

-

Gino Iorfida

- Posts: 568

- Joined: 27 Sep 2002 12:01 am

- Location: Pittsburgh, Pennsylvania, USA

- Contact:

McMaster Carr www.mcmaster.com has the stainless welding rods, in the right length (much cheaper than the 'raw materials' stainless as well!!)... It's been a while, but it used to be around $10 for a pack of 10 rods, 1/8" x 3ft long .... they also would carry the die you need to thread your own

- Mike Wheeler

- Posts: 3058

- Joined: 18 Oct 2004 12:01 am

- Location: Delaware, Ohio, USA

Just to bring you all up to date.....

I bought a couple 6 ft., type 416, stainless rods, the 5-40 die and the stock (handle) from McMaster-Carr. Terrific prices and unbelieveably fast shipping. I really should have bought a few more rods because the shipping for that 6 foot tube was high and extra rods wouldn't have raised it, but live and learn, right? Also, I found out that type 303 would have been a better choice for the rods, but 416 is OK.

Again, thanks to everyone for all the help. I'm a dummy when it comes to metalurgy and machine shop stuff.

This sure proved the value of this forum....friends helping friends. Ya gotta love it...I know I do!!

I bought a couple 6 ft., type 416, stainless rods, the 5-40 die and the stock (handle) from McMaster-Carr. Terrific prices and unbelieveably fast shipping. I really should have bought a few more rods because the shipping for that 6 foot tube was high and extra rods wouldn't have raised it, but live and learn, right? Also, I found out that type 303 would have been a better choice for the rods, but 416 is OK.

Again, thanks to everyone for all the help. I'm a dummy when it comes to metalurgy and machine shop stuff.

This sure proved the value of this forum....friends helping friends. Ya gotta love it...I know I do!!

Best regards,

Mike

Mike