Excel Keyless 3rd string

Moderator: Shoshanah Marohn

- richard burton

- Posts: 3846

- Joined: 23 Jan 2001 1:01 am

- Location: Britain

-

James Quackenbush

- Posts: 2966

- Joined: 27 Sep 2002 12:01 am

- Location: Pomona, New York, USA

-

James Quackenbush

- Posts: 2966

- Joined: 27 Sep 2002 12:01 am

- Location: Pomona, New York, USA

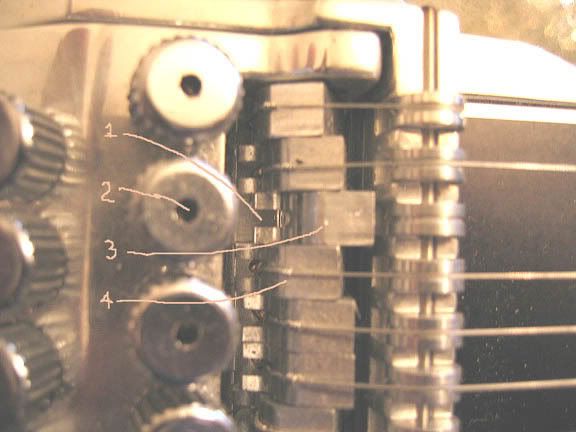

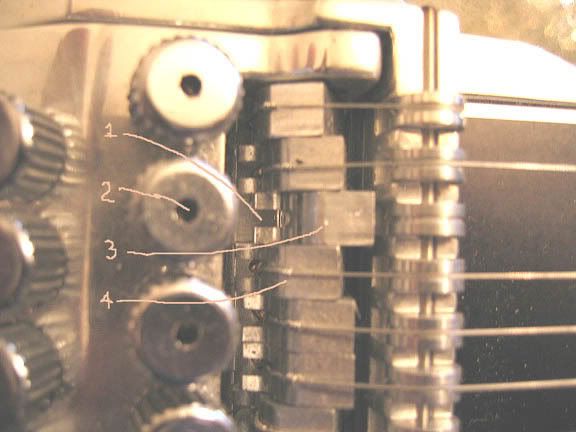

1) This is a fork that holds the ball end of the string when it's being tightened

2) This is where an allen wrench goes in and turns the screw to move what I will call the "string puller" back to tighten the string

3) The last string that broke left this burr, but it was not there the rest of the time when I was trying to string this steel up...

4) Notice where the end of the wire wrap is on the string puller .....This is where it is snapping all the time....I will show another picture of the dead soldiers !!....

<font size="1" color="#8e236b"><p align="center">[This message was edited by James Quackenbush on 26 December 2006 at 02:22 PM.]</p></FONT>

<font size="1" color="#8e236b"><p align="center">[This message was edited by James Quackenbush on 26 December 2006 at 02:22 PM.]</p></FONT>

2) This is where an allen wrench goes in and turns the screw to move what I will call the "string puller" back to tighten the string

3) The last string that broke left this burr, but it was not there the rest of the time when I was trying to string this steel up...

4) Notice where the end of the wire wrap is on the string puller .....This is where it is snapping all the time....I will show another picture of the dead soldiers !!....

<font size="1" color="#8e236b"><p align="center">[This message was edited by James Quackenbush on 26 December 2006 at 02:22 PM.]</p></FONT>

<font size="1" color="#8e236b"><p align="center">[This message was edited by James Quackenbush on 26 December 2006 at 02:22 PM.]</p></FONT>-

James Quackenbush

- Posts: 2966

- Joined: 27 Sep 2002 12:01 am

- Location: Pomona, New York, USA

- Michael Johnstone

- Posts: 3841

- Joined: 29 Oct 1998 1:01 am

- Location: Sylmar,Ca. USA

10s have to stretch more than an .011 to raise a half-step on a 25.5" scale causing them to break more often - besides,they sound a bit thin. 12s have to stretch less when pedaled but have to have more tension in the first place to get up to G# which is a formula for more string breakage on a 25.5" guitar. So we're left with .011 or .0115 as the optimum gauge string for a long scale guitar. That's been my experience anyway.

-

James Quackenbush

- Posts: 2966

- Joined: 27 Sep 2002 12:01 am

- Location: Pomona, New York, USA

I was near my local music store today, and bought some D'Adarridario' s or however you spell it , and they were .011's and I also bought .012's ....These strngs just came into the store last week .... I know the owner , and he has no reason to lie to me ... MORE DEAD SOLDIERS !!

I wish I knew the trick !!....This is getting really old !!...I m afraid to change the rest of my strings now !!.... I'll talk to Don Curtis at Scotties tomorrow .....Maybe he can shed some light on this problem...I'm just beside myself ... I've tried 4 different brands, and 2 different gauges of strings, and they ALL break !!.... ????????.. ....Jim

....Jim

I wish I knew the trick !!....This is getting really old !!...I m afraid to change the rest of my strings now !!.... I'll talk to Don Curtis at Scotties tomorrow .....Maybe he can shed some light on this problem...I'm just beside myself ... I've tried 4 different brands, and 2 different gauges of strings, and they ALL break !!.... ????????..

....Jim

....Jim- Karlis Abolins

- Posts: 714

- Joined: 30 Mar 2002 1:01 am

- Location: (near) Seattle, WA, USA

James, I ran your strings though my string calculator and found that your .011 string would have a tension of over 35 lbs. when pulled to an A. I can see why you are snapping strings. I would recommend a .0105 for the 3rd string. When pulled to an A, a .0105 has a tension of 31.8 lbs. If you used a .010 string, it would have an tension of 28.9 lbs when pulled to an A, maybe a bit too flabby.

A .011 string on a 24" scale has a tension of 31 lbs. when pulled to an A.

Karlis

A .011 string on a 24" scale has a tension of 31 lbs. when pulled to an A.

Karlis

- Michael Johnstone

- Posts: 3841

- Joined: 29 Oct 1998 1:01 am

- Location: Sylmar,Ca. USA

AHA! That's Mitsuo's latest design w/finger tuners and where the strings go on backwards. On the earlier one that I have - maybe 3 years old,the strings go on normally w/the beads on the changer end and the tuning system is quite different.No finger tuneres on mine - hex key only and plus mine has little vertical moving sleds w/no sharp angles.Mine never breaks strings.

This problem is not about string brands,string gauges or scale lengths - it's about sharp edges.

From the photos you posted it looks like the strings lay right on a sharp enough angle to break them right where they've been breaking when tension is applied while tuning up. You might try getting out your jewelers files and rounding and polishing that angle.I think that would help quite a bit and probably solve the issue.<font size="1" color="#8e236b"><p align="center">[This message was edited by Michael Johnstone on 26 December 2006 at 02:38 PM.]</p></FONT>

This problem is not about string brands,string gauges or scale lengths - it's about sharp edges.

From the photos you posted it looks like the strings lay right on a sharp enough angle to break them right where they've been breaking when tension is applied while tuning up. You might try getting out your jewelers files and rounding and polishing that angle.I think that would help quite a bit and probably solve the issue.<font size="1" color="#8e236b"><p align="center">[This message was edited by Michael Johnstone on 26 December 2006 at 02:38 PM.]</p></FONT>

-

James Quackenbush

- Posts: 2966

- Joined: 27 Sep 2002 12:01 am

- Location: Pomona, New York, USA

Michael,

EXACTLY what I did about 10 minutes ago ( polished the edge )...No cigar !!... I just broke another string .... I need the forks that hold the ball of the string on TOP of the string holder, not on the inside bottom as shown in the number 1 in the photo ... This has to be a design flaw, and I would venture to say that there is only one string ( the SIT extra something or other) that will hold with this design ...Either that or I am going to have to have these string WELDED CLOSED !!!.... I'm gonna have to contact Scottie about this...I can't keep fighting with this thing !!...I'm getting ready to throw it thru a window !!... ....Jim

....Jim

EXACTLY what I did about 10 minutes ago ( polished the edge )...No cigar !!... I just broke another string .... I need the forks that hold the ball of the string on TOP of the string holder, not on the inside bottom as shown in the number 1 in the photo ... This has to be a design flaw, and I would venture to say that there is only one string ( the SIT extra something or other) that will hold with this design ...Either that or I am going to have to have these string WELDED CLOSED !!!.... I'm gonna have to contact Scottie about this...I can't keep fighting with this thing !!...I'm getting ready to throw it thru a window !!...

....Jim

....Jim- Michael Johnstone

- Posts: 3841

- Joined: 29 Oct 1998 1:01 am

- Location: Sylmar,Ca. USA

That new tuning head design would be fine if it wasn't for the fact that strings tend to be manufactured with the ends of the windings laying right across a sharp edge.That one spot on the string seems to be a weak area and one that can't take that kind of flexing or abuse. I'd ask Mitsuo if your steel can be retrofitted with the older style tuning head. You could probably change it out yourself. Also,upon carefully re-reading all your posts in this thread,you never mentioned whether you've tried Jagwire strings. If you haven't,before you do anything drastic,you should try a Jagwire .011 on there. It could be the answer.I find it to be the best string available.

-

tom anderson

- Posts: 591

- Joined: 13 Dec 1999 1:01 am

- Location: leawood, ks., usa

-

James Quackenbush

- Posts: 2966

- Joined: 27 Sep 2002 12:01 am

- Location: Pomona, New York, USA

Don is still not back from the Christmas holiday....

I sent an email to Mitsuo along with a link to the forum thread .....

I wish I knew how the original string lasted as long as it did ... I figured I would have no problem with a new string after the original lasting almost a year !!

I have noticed that the original strings do have some pretty heavy windings on them ..Much heavier than the strings I have tried to put on ...Does anybody know what strings have HEAVY windings for their gauge ?...

Jon,

I have run out of strings...I have more coming from b0b as we speak....I have some beads here that I will try ...Good Idea ...I hope it works....Maybe too the Jagwire strings will have a short enough wind to get the job done....

I used some 500 grit emery paper to smooth out the edge on the string puller ...The string STILL broke at the same location...I'm hoping that if I can get the winding to NOT lay on the string puller at all, that I might stand a chance ...

I sent an email to Mitsuo along with a link to the forum thread .....

I wish I knew how the original string lasted as long as it did ... I figured I would have no problem with a new string after the original lasting almost a year !!

I have noticed that the original strings do have some pretty heavy windings on them ..Much heavier than the strings I have tried to put on ...Does anybody know what strings have HEAVY windings for their gauge ?...

Jon,

I have run out of strings...I have more coming from b0b as we speak....I have some beads here that I will try ...Good Idea ...I hope it works....Maybe too the Jagwire strings will have a short enough wind to get the job done....

I used some 500 grit emery paper to smooth out the edge on the string puller ...The string STILL broke at the same location...I'm hoping that if I can get the winding to NOT lay on the string puller at all, that I might stand a chance ...

-

James Quackenbush

- Posts: 2966

- Joined: 27 Sep 2002 12:01 am

- Location: Pomona, New York, USA

I spoke with Don Curtis at Scotties and he was very helpful...We are going thru it step by step ...I will first be trying out a few different reinforced strings to see if one will hold...I also have 2 different gauged Jagwire strings coming from b0b ...I will take it from there...I will keep you all posted .... Thanks to all for your help...Sincerely, Jim

- richard burton

- Posts: 3846

- Joined: 23 Jan 2001 1:01 am

- Location: Britain

-

Roland Buras

- Posts: 446

- Joined: 26 Jul 2001 12:01 am

- Location: Kiln, MS, 45 miles east of New Orleans off I-10 USA

Hi Jim, Bill Stafford asked me to write you concerning string breakage on your excel. I personally have three Excels, My first a 2002 SD12 8x5 with the string load from the changer "Rear" to the set screw on the front keyless tuning, never in four years broke one string.

I have since purchased a 2004 and a 2005 both SD12 9x7 superbs. I have expierinced two problems i had {not the Guitar} first mistake was putting on a regular electric 011 guitar string designed for 6 string guitar and not steel. The second was tightning the G# 3rd set screw to tight and cut the string. one other for me was looking at the keyless tuning from the front on my 2002 i had put my string to the left of the set screw and that would snap it every time. for me the string on the right side of the set screw was the proper way to string the keyless tuner. and do not tighten the string to hard. on the 2004 ans 2005 they string with the ball at the keyless tuner end and tighten at the changer set screw.

The above problems had nothing to do with the mechanicals or workmanship of the guitar, yet simply an error and oversight on my part. after resolving my problem i have not broken a string.

I use Bill Staffords gauges, ghs and Sit, steel guitar strings and Billy Carr's, George L's

Goodluck

R J Buras, Mississippi Gulf coast

I have since purchased a 2004 and a 2005 both SD12 9x7 superbs. I have expierinced two problems i had {not the Guitar} first mistake was putting on a regular electric 011 guitar string designed for 6 string guitar and not steel. The second was tightning the G# 3rd set screw to tight and cut the string. one other for me was looking at the keyless tuning from the front on my 2002 i had put my string to the left of the set screw and that would snap it every time. for me the string on the right side of the set screw was the proper way to string the keyless tuner. and do not tighten the string to hard. on the 2004 ans 2005 they string with the ball at the keyless tuner end and tighten at the changer set screw.

The above problems had nothing to do with the mechanicals or workmanship of the guitar, yet simply an error and oversight on my part. after resolving my problem i have not broken a string.

I use Bill Staffords gauges, ghs and Sit, steel guitar strings and Billy Carr's, George L's

Goodluck

R J Buras, Mississippi Gulf coast

-

Rick Nicklas

- Posts: 963

- Joined: 14 Nov 1998 1:01 am

- Location: Verona, Mo. (deceased)

Jim, I sincerely hope you resolve your problem.... but in the meantime, I do think you should apply for "The Most String Breakage on Pedal Steel" in Guiness Records. I have participated in Clothing Drives before but I think we are going to have to start a String Drive for you. Hope Don can get the right answers for you.... Rick

-

ed packard

- Posts: 2162

- Joined: 4 Aug 1998 11:00 pm

- Location: Show Low AZ

-

James Quackenbush

- Posts: 2966

- Joined: 27 Sep 2002 12:01 am

- Location: Pomona, New York, USA

Roland and friends,

Thanks for your replies...

Roland ,

My steel is a newer model and is only 9 mos old ...I have the model ( look at my pictures here in this tread )that has the ball attached under a fork on the tuner end of the steel which sounds like your 2005 model that you described...The string is NOT breaking at the changer end of the pedal steel from the screws ..It is breaking at the tuner end ...Take a look at my pictures , and you will be able to clearly see on your 2005 tuner where my strings are breaking ....Thanks for your reply ...Every reply is very helpful...

Don Curtis from Scotties seem's to think that if I put on some reinforced strings on it , that they will do the trick ... The strings that are on my steel know look to have heavier windings on them ...This could be the reinforced strings that Don is talking about ... He is sending me 2 strings from 4 different manufacturers for me to try out ...This will be step one, and hopefully the final step in the process of figuring out what's up with my steel ..

Don assured me that he would go to any length to remedy this problem !!...THIS my friends is customer service at it's best ..I would not hesitate for one minute to buy another steel from Scotty and Don in the future ... They really do care about their customers !!....

Ed,

I'll try that electrical tape to see how it works ...

As far as going into the Guiness book of world records, I hope this will be resolved soon, or I will be going into the record books for drinking the most Guiness while attempting to change a 3rd string on a pedal steel !!...( Not really...I've been sober since 1988 thank God !! ) ..Jim

Thanks for your replies...

Roland ,

My steel is a newer model and is only 9 mos old ...I have the model ( look at my pictures here in this tread )that has the ball attached under a fork on the tuner end of the steel which sounds like your 2005 model that you described...The string is NOT breaking at the changer end of the pedal steel from the screws ..It is breaking at the tuner end ...Take a look at my pictures , and you will be able to clearly see on your 2005 tuner where my strings are breaking ....Thanks for your reply ...Every reply is very helpful...

Don Curtis from Scotties seem's to think that if I put on some reinforced strings on it , that they will do the trick ... The strings that are on my steel know look to have heavier windings on them ...This could be the reinforced strings that Don is talking about ... He is sending me 2 strings from 4 different manufacturers for me to try out ...This will be step one, and hopefully the final step in the process of figuring out what's up with my steel ..

Don assured me that he would go to any length to remedy this problem !!...THIS my friends is customer service at it's best ..I would not hesitate for one minute to buy another steel from Scotty and Don in the future ... They really do care about their customers !!....

Ed,

I'll try that electrical tape to see how it works ...

As far as going into the Guiness book of world records, I hope this will be resolved soon, or I will be going into the record books for drinking the most Guiness while attempting to change a 3rd string on a pedal steel !!...( Not really...I've been sober since 1988 thank God !! ) ..Jim

-

ed packard

- Posts: 2162

- Joined: 4 Aug 1998 11:00 pm

- Location: Show Low AZ

-

Michael Brewer

- Posts: 176

- Joined: 2 Mar 2001 1:01 am

- Location: Carrollton, Texas

- Contact:

Jim Q, -

I hve had my Excel Superb for a little over a year and have never broken a string. Perhaps it is because I use the Bflat 6th tuning and all my string sizes are larger. MY string three is .014.

One thing I have noted is that if you are not careful, the twist will ride up onto the roller and the string will not lie down into the roller notch. This could be a contributor to your problem.

After I saw the pictures of your guitar I realized that you have the fingertip tuners. A normal twist cannot reach your rollers.

How do you like the fingertip tuners? I am thinking about modifying my guitar to add them. Using the allen wrench to tune is about the only thing I don't like about this guitar

I hve had my Excel Superb for a little over a year and have never broken a string. Perhaps it is because I use the Bflat 6th tuning and all my string sizes are larger. MY string three is .014.

One thing I have noted is that if you are not careful, the twist will ride up onto the roller and the string will not lie down into the roller notch. This could be a contributor to your problem.

After I saw the pictures of your guitar I realized that you have the fingertip tuners. A normal twist cannot reach your rollers.

How do you like the fingertip tuners? I am thinking about modifying my guitar to add them. Using the allen wrench to tune is about the only thing I don't like about this guitar

Mike Brewer

-

James Quackenbush

- Posts: 2966

- Joined: 27 Sep 2002 12:01 am

- Location: Pomona, New York, USA

Michael,

The fingertip tuners are very nice....You have to have some pretty strong fingers to turn them however ....Not really a problem as in the middle of the tuners is a hole for an allen key which comes with the pedal steel when you buy it ... Perhaps over time they will loosen up some ....

One thing that I have come to find is that the edge on the string puller that put's the tension on the string when tuning it up is not really the culprit here .....I got some Jagwire strings which have shorter windings and what is happening is that the string is breaking at the end of the wind, no matter WHERE the wind is on the string puller.... My thoughts are that there are a few different workarounds for this ...

1) Make the string puller radius larger so that there is not as much of a sharp radius which will ease the tension some ....

2) The string puller has a fork that holds the ball at 9 o'clock .....If the fork that holds the ball end of the string were at 11 o'clock to 12 o'clock then the string would have more of a straight pull, and the winding would not be sitting on the string puller.. The string roller still sits higher than the string puller, so there would still be enough downward force on the roller ...

3) Use reinforced strings ESPECIALLY on the 3rd string .....This is what I think was originally used on this steel .... I'll know better when I get the strings....

The Jagwires came very close to working , but still snapped...I'm going to try to put some electrical tape or drink stirrers or something soft as Ed has mentioned, to see if that will help ... If not, I would hope that the reinforced strings that Don Curtis is sending me will do the trick ... I would be willing to bet that if I had the forks up higher , that the strings would not break at all ...If you look at a Williams 400 changer end , and see how the strings are mounted with a slight angle , THIS is what I would like to see on the tuner end of my Excel ...Just a slight angle, and not wrapped at a full 90 degrees around the string tuner ... If the reinforced strings work, I don't have to go any further, and everything else would be a moot point , but still worth noting for the new and improved edition Excel ... Maybe one with interchangeable pickups too !!.... One can only dream !!.....I will not sell my Excel ...Whatever it takes to fix it , I will do .....I'm still loving this steel even though I'm going thru a tough time ....I know that it will be remedied ....It's still the steel that I want to play , and will be smiling again soon ... I have a lot of people pulling for me to get this steel right , and I know it will happen ....I'm even learning how to be patient !!.... Geeesh !!!...How in the world did that happen ???.....Happy New Year to all , and thanks to all of you for helping me out with this problem .... That's the best part of being a member of this forum, and why I support it .... When you have a problem , it's family here , and it's everybody's problem !!...God bless you all !!....Sincerely, Jim

The fingertip tuners are very nice....You have to have some pretty strong fingers to turn them however ....Not really a problem as in the middle of the tuners is a hole for an allen key which comes with the pedal steel when you buy it ... Perhaps over time they will loosen up some ....

One thing that I have come to find is that the edge on the string puller that put's the tension on the string when tuning it up is not really the culprit here .....I got some Jagwire strings which have shorter windings and what is happening is that the string is breaking at the end of the wind, no matter WHERE the wind is on the string puller.... My thoughts are that there are a few different workarounds for this ...

1) Make the string puller radius larger so that there is not as much of a sharp radius which will ease the tension some ....

2) The string puller has a fork that holds the ball at 9 o'clock .....If the fork that holds the ball end of the string were at 11 o'clock to 12 o'clock then the string would have more of a straight pull, and the winding would not be sitting on the string puller.. The string roller still sits higher than the string puller, so there would still be enough downward force on the roller ...

3) Use reinforced strings ESPECIALLY on the 3rd string .....This is what I think was originally used on this steel .... I'll know better when I get the strings....

The Jagwires came very close to working , but still snapped...I'm going to try to put some electrical tape or drink stirrers or something soft as Ed has mentioned, to see if that will help ... If not, I would hope that the reinforced strings that Don Curtis is sending me will do the trick ... I would be willing to bet that if I had the forks up higher , that the strings would not break at all ...If you look at a Williams 400 changer end , and see how the strings are mounted with a slight angle , THIS is what I would like to see on the tuner end of my Excel ...Just a slight angle, and not wrapped at a full 90 degrees around the string tuner ... If the reinforced strings work, I don't have to go any further, and everything else would be a moot point , but still worth noting for the new and improved edition Excel ... Maybe one with interchangeable pickups too !!.... One can only dream !!.....I will not sell my Excel ...Whatever it takes to fix it , I will do .....I'm still loving this steel even though I'm going thru a tough time ....I know that it will be remedied ....It's still the steel that I want to play , and will be smiling again soon ... I have a lot of people pulling for me to get this steel right , and I know it will happen ....I'm even learning how to be patient !!.... Geeesh !!!...How in the world did that happen ???.....Happy New Year to all , and thanks to all of you for helping me out with this problem .... That's the best part of being a member of this forum, and why I support it .... When you have a problem , it's family here , and it's everybody's problem !!...God bless you all !!....Sincerely, Jim

- Curt Langston

- Posts: 2907

- Joined: 3 Apr 2000 12:01 am

Thats fine and all, but you should be able to put any set of strings on that guitar. That is a 3500.00 guitar!Don Curtis from Scotties seem's to think that if I put on some reinforced strings on it , that they will do the trick ...

My Pedalmaster has a keyless 25 inch scale, and it simply does not break strings. Here is a pic of my tuner:

I fear you may have a design flaw.

As far as lightly polishing the sharp edge: It might help, but perhaps it would void the warranty?

Electrical tape: I would not do. Any help it MAY provide, would be overshadowed by the dampening effect on sustain.

Plus, it would look "rigged", and you don't want that on your new guitar.

My 2 cents:

Send it back to Mujitso for a precision remachining. He will stand by has work, just as Scotty will.

Be careful "doctoring" it up!

- Michael Johnstone

- Posts: 3841

- Joined: 29 Oct 1998 1:01 am

- Location: Sylmar,Ca. USA

Here's a fix that I know will work. Drill and tap holes that will accept 10/32 inside hex head machine screws dead center in the top facet of the string pulling arm. Then it will look like the picture of my tuning head I sent you and also like the Pedalmaster head pic just posted,the Kline head,Sierra head and a couple others. Then you will just not use the bead at all and will wrap the strings around a screw at both ends of the guitar - or devise a way to anchor the bead end (maybe on a pin) at the changer like most guitars do. It'll work I gaurantee you as long as the top of that facet is low enough to provide some angle up to the roller nut. One other possibility is to put a hard steel pin on the second facet and hook the bead on that pin like an Emmons PP.That way you'll have the windings laying further up on the pulling arm and not have that strings weak spot right on that break angle - I'd betcha that would also work.