My question has to do with the adjustments on the arms. Of course I will need the bender adjustment which allows the player to tune the pitch of the raised tone when pressing on the handle.

But why is an adjustment needed when the handle is released and at rest? Unless I am missing something, that tone is already adjusted with the tuners at the other end of the guitar.

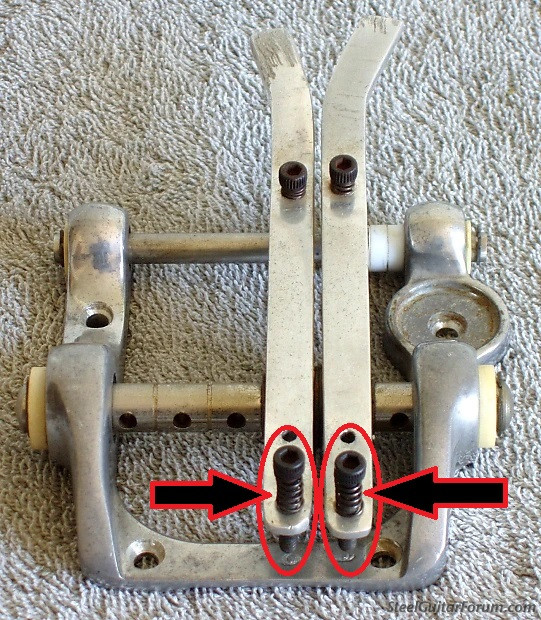

The adjustment I am talking about is in the red circles in the photo below. Obviously, some sort of "stop" will be necessary but for the life of me I cannot see why it has to be adjustable. Any ideas?