| Author |

Topic: How to convert a 6 string dobro to a 8 string? |

Thomas Cross

From:

Magnolia,Texas, USA

|

Posted 7 Feb 2011 9:33 pm

Posted 7 Feb 2011 9:33 pm |

|

| What has to be done to convert a 6 string to 8 string besides adding to string? tfc |

|

|

|

Jason Hull

|

Posted 8 Feb 2011 3:56 am

Posted 8 Feb 2011 3:56 am |

|

Last edited by Jason Hull on 27 Apr 2012 10:51 am; edited 1 time in total |

|

|

|

Robert Murphy

From:

West Virginia

|

Posted 8 Feb 2011 5:31 am

Posted 8 Feb 2011 5:31 am |

|

| I am not the expert on this but I've owned an 8 string custom and 6 to 7 string converted guitars. To convert to 8 strings can overpower the cone and/or the structure of the guitar. The 8 string custom was built with that kind of tension in mind. Paul Beard or Greg McKenna are the best source of REAL information. |

|

|

|

John Allison

From:

Austin, Texas, USA

|

Posted 8 Feb 2011 6:20 am

Posted 8 Feb 2011 6:20 am |

|

I converted a couple of inexpensive Chinese-made dobro style 6-stringers and they turned out fine. Just made a new saddle and a nut that hung over the edges of the neck. The two outer strings are sort of out there in mid air, but it's not too unwieldy.

The pressure on the cone will increase, of course, but it really depends on your tuning and string guages. When it was all said and done, a relatively heavy guage tuned to A6 worked well and sounded quite good.

I wouldn't suggest doing it on a nice instrument - you'd want to find one that's purpose-built. On the other hand if you want, like my customer did, an inexpensive instrument to use for casual acoustic gigs or jams, it's a good way to go.

I'll see if I can post a quick picture later on.

_________________

John Allison

Allison Stringed Instruments

Austin, Texas

www.allisonguitars.com |

|

|

|

Sonny Jenkins

From:

Texas Masonic Retirement Center,,,Arlington Tx

|

Posted 8 Feb 2011 10:46 am

Posted 8 Feb 2011 10:46 am |

|

Here is a Rogue I converted several years ago,,,just play it around the house,,,still trying to improve it,,,Billy Gilbert has helped with it,,and Carroll Benoit is making me a nut for it. I will eventually change the fretboard so the strings don't "hang over.

|

|

|

|

Lynn Oliver

From:

Redmond, Washington USA * R.I.P.

|

Posted 8 Feb 2011 12:04 pm

Posted 8 Feb 2011 12:04 pm |

|

| I think you can decrease the extra loading on the cone by raising the tailpiece. |

|

|

|

Jason Hull

|

Posted 8 Feb 2011 3:18 pm

Posted 8 Feb 2011 3:18 pm |

|

Last edited by Jason Hull on 27 Apr 2012 10:51 am; edited 1 time in total |

|

|

|

Steve Branscom

From:

Pacific NW

|

Posted 8 Feb 2011 4:54 pm

Posted 8 Feb 2011 4:54 pm |

|

Paul Beard and Gregg McKenna build 8 string dobros for a living. I'm sure they have experience well surpassing what the forum has. Wouldn't you want to avail yourself of that information especially if it was just a phone call away and it didn't cost you anything. I appreciate the comments and the experience of the forum but would defer to Paul Beard and Gregg McKenna given the choice and opportunity.

_________________

Steve |

|

|

|

Jason Hull

|

Posted 9 Feb 2011 6:03 pm

Posted 9 Feb 2011 6:03 pm |

|

Last edited by Jason Hull on 27 Apr 2012 10:52 am; edited 1 time in total |

|

|

|

Brad Bechtel

From:

San Francisco, CA

|

Posted 10 Feb 2011 7:46 am

Posted 10 Feb 2011 7:46 am |

|

I certainly would trust the word of a professional luthier who has experience building both six and eight string guitars over that of some schmoe on the internet. But then again, it's your guitar. I'm sure whichever path leads you to the results you get is the right path for you.

I would guess that Beard and McKenna started out modifying dobros they had available to them before building their own guitars, and I would guess that this was long before the internet made such information easily available. Who knows where the next fine luthiers are coming from?

_________________

Brad’s Page of Steel

A web site devoted to acoustic & electric lap steel guitars |

|

|

|

John Allison

From:

Austin, Texas, USA

|

Posted 10 Feb 2011 9:04 am

Posted 10 Feb 2011 9:04 am |

|

| Brad Bechtel wrote: |

| ...over that of some schmoe on the internet. |

Brad, just for the record, who are you calling a "schmoe"!!!

I'm not one to take offense at offhanded, uninformed remarks, but you might want to think twice before you spout off.

Since I am a full time professional luthier and have been for going on 30 years and have recently done the exact conversion that is the exact subject of this thread, I think I can offer some "real" information on the subject. In fact, precisely the sort of information requested in the original question.

_________________

John Allison

Allison Stringed Instruments

Austin, Texas

www.allisonguitars.com |

|

|

|

Brad Bechtel

From:

San Francisco, CA

|

Posted 10 Feb 2011 7:51 pm

Posted 10 Feb 2011 7:51 pm |

|

John, I'm not at all implying that you're not qualified to render an opinion; far from it. I just think that the original answer by Mr. Murphy was misinterpreted. I think that the SGF is a great resource for exactly this sort of thing, but if you really want information, sometimes it's best to go to the people who do this regularly. Of course you fit in that category, and I would respect any opinion you have on the matter.

What I was referring to by the term "some schmoe on the internet" was the frequent situation where somebody says (for example) "I heard that xx brand guitars were made of cardboard" and someone else says "no, they're made of toilet paper" - when asking the person who made the guitar would answer the question properly.

_________________

Brad’s Page of Steel

A web site devoted to acoustic & electric lap steel guitars |

|

|

|

John Allison

From:

Austin, Texas, USA

|

Posted 11 Feb 2011 5:21 am

Posted 11 Feb 2011 5:21 am |

|

Brad, I didn't take offense. I understood that your comment was directed toward the general internet exchange, which, as you indicate, is less than a perfect filter when it comes to getting useful information.

I didn't mean to come off as snooty, and I realize that my post could sound that way - another trouble with the text-centric communication that's pervasive these days. Nuances are lost and casual conversations in written form just don't always give a clear picture.

_________________

John Allison

Allison Stringed Instruments

Austin, Texas

www.allisonguitars.com |

|

|

|

Ben Elder

From:

La Crescenta, California, USA

|

Posted 11 Feb 2011 11:56 pm Whatever you do...

Posted 11 Feb 2011 11:56 pm Whatever you do... |

|

...don't do it like this:

I got this at a great price here on the Forum, but I could cry at the ham-handed desecration that Goober and Jethro visited on this once-proud late-30s Regal-made Dobro*.

First of all, the tuners. OK, you're trying to crowd eight into space for six. So you changed to full-size Schallers for the original six? And you don't screw them in--just tighten them down with a hex nut and washer from the front? The added Cheapanese tuners at the bottom of the headstock don't tune 8 and 1--but 7 and 2--and turn backwards from the other six.

Since you're on a roll there, professors, make a sloppy aluminum nut and be sure to swill a gallon or two of Granny's corn squeezin's before slotting and gluing it. Be sure to allow it to tilt away from perpendicular and slop the epoxy all over the headstock and south forty.

While you're making that bone saddle (please don't tell me who you made it out of) why'nt'cha just make it go all the way over the cone center-screw. Who'd ever want to tighten it to get rid of rattles and improve the tone anyway? And once you put everything back in place, be sure to put the cover on upside down with the patent number above the bridge.

I'm really hoping I won't like this as a eight-string so I'll have just the slightest excuse to turn it back into a six. But so far, even with my make-do/mix-n-match set of 80/20 and phosphor bronze strings, that's not the case.

*--This is a model sometimes seen labeled Norwood Chimes--a (Montgomery) Wards brand. This has the Wards sticker inside the body, too. Before the Sho-Bro, this was the model favored by Shot Jackson and he's seen in many old photos with one of these.

It's a larger than normal body--jumbo as Dobros go--with an arched back that was designed for a (non-resonator?) model that never went into production. According to an interview with John Dopyera in Beverly King's Dobro Nut/Resophonic Echoes/Country Heritage, to adapt these bodies as resonator instruments, they had to make the neck 13 frets to the body in order to make the scale and resonator placement work out.

_________________

"Gopher, Everett?" |

|

|

|

Alan Brookes

From:

Brummy living in Southern California

|

Posted 12 Feb 2011 10:56 am

Posted 12 Feb 2011 10:56 am |

|

Use mandolin tuners. The distance between the the outside tuners is the same on a guitar and a mandolin. Just plug up the middle holes in the peghead with dowelling and drill two new ones. It doesn't matter if the new nut is wider than the neck.

And yes, the average resonator cone will take the weight of the extra two strings. I've seen it done will twelve strings, and I've done it myself with 8 strings. The limitation is mainly the space in the coverplate.

http://bb.steelguitarforum.com/viewtopic.php?t=117146&highlight=conversion

Check out the above.

Last edited by Alan Brookes on 13 Feb 2011 5:20 pm; edited 1 time in total |

|

|

|

Howard Parker

From:

Maryland

|

Posted 12 Feb 2011 12:45 pm

Posted 12 Feb 2011 12:45 pm |

|

FWIW I know that Paul converted a bunch of Flinthills to eight string using the same tuner arrangement that Sonny used. At that time (pre Gold Tone) Paul preferred the Flinthill for conversion because the neck was a tad wider than the other Asian imports available. That enabled him to use his standard 8 string string spacing. He also used the standard 8 string spacing on other import necks, advising the customers that there would be a wee bit of overhand. Everyone got used to it.

The conversions became a moot point when the PBS-8's became available.

I always referred to the conversions as having the "My Favorite Martian" look about them.

And there you have it...Have fun.

h

_________________

Howard Parker

03\' Carter D-10

70\'s Dekley D-10

52\' Fender Custom

Many guitars by Paul Beard

|

|

|

|

Gregg McKenna

From:

South Windsor, Connecticut, USA

|

|

|

|

Alan Brookes

From:

Brummy living in Southern California

|

Posted 19 Feb 2011 9:04 am

Posted 19 Feb 2011 9:04 am |

|

That's exactly what I did on my conversion, and it shows an important point, that you should never drill holes directly into a polished or metal surface without first covering it with masking tape. This prevents the drill running all over the place and engraving a mess.

By the way, it's worth noting that it's virtually impossible to drill holes in exactly the right place with a hand drill. You need to first indent the location with a drill punch, and drill a pilot hole with a small drill bit, then follow it with a drill bit of the right size. Alternatively, use a drill press.

Last edited by Alan Brookes on 19 Feb 2011 3:03 pm; edited 1 time in total |

|

|

|

Mark Eaton

From:

Sonoma County in The Great State Of Northern California

|

Posted 19 Feb 2011 9:40 am

Posted 19 Feb 2011 9:40 am |

|

| Quote: |

| I would guess that Beard and McKenna started out modifying dobros they had available to them before building their own guitars, and I would guess that this was long before the internet made such information easily available. |

Good to see Gregg chime in on this thread, and I'm guessing that he, Paul Beard, and Ivan Guernsey, whose guitars Mike Auldridge played for a number of years, didn't construct their early 8 strings out of thin air.

I had a dobro teacher in 1977 who liked the sound of my pre-war circa 1930 Dobro so much that he offered me an S-10 pedal steel and a newish at the time 8 string OMI Dobro in trade for it. So the 8 string resonator guitar concept has been around for quite a few years, and there were examples of the instrument built by the Dopyeras.

_________________

Mark |

|

|

|

chas smith R.I.P.

From:

Encino, CA, USA

|

Posted 19 Feb 2011 10:43 am

Posted 19 Feb 2011 10:43 am |

|

| I don't have any pics, but way back in the early '80s, I converted a 10 string Dobro to a 12-string, with the addition of a couple banjo tuners and I made a wider nut and bridge. It worked very well, except for the crushed cone and the cracked spider, which didn't improve the tone. |

|

|

|

Steve Ahola

From:

Concord, California

|

Posted 19 Feb 2011 11:22 am

Posted 19 Feb 2011 11:22 am |

|

| chas smith wrote: |

| I don't have any pics, but way back in the early '80s, I converted a 10 string Dobro to a 12-string, with the addition of a couple banjo tuners and I made a wider nut and bridge. It worked very well, except for the crushed cone and the cracked spider, which didn't improve the tone. |

LOL  |

|

|

|

Alan Brookes

From:

Brummy living in Southern California

|

Posted 19 Feb 2011 3:07 pm

Posted 19 Feb 2011 3:07 pm |

|

| You can adjust the pressure on the cone by adjusting the angle of the string to the bridge. Imagine if the strings passed over the bridge barely touching it. There would be virtually no downward pressure. As you sharpen the angle the pressure changes. You should be able to put as many strings on as you like without damaging the cone as long as you make the angle at the bridge more gradual. Of course, if you reduce the pressure too much the strings will rattle. |

|

|

|

Gregg McKenna

From:

South Windsor, Connecticut, USA

|

Posted 19 Feb 2011 6:17 pm

Posted 19 Feb 2011 6:17 pm |

|

| Alan Brookes wrote: |

That's exactly what I did on my conversion, and it shows an important point, that you should never drill holes directly into a polished or metal surface without first covering it with masking tape. This prevents the drill running all over the place and engraving a mess.

By the way, it's worth noting that it's virtually impossible to drill holes in exactly the right place with a hand drill. You need to first indent the location with a drill punch, and drill a pilot hole with a small drill bit, then follow it with a drill bit of the right size. Alternatively, use a drill press. |

I usually use a 10 penny finish nail I ground to a point as a punch to start the hole and start with a 7/64 bit and work up to a 3/16 bit for the holes. You can keep from having the bit grab too hard by starting the holes with the drill running in reverse, then change it back. I use a jig saw blade with all the teeth ground down to rough out the slots, then finish with files which is somewhat time consuming but seems to work best for me.

Using the hand electric drill seems to work better than the drill press because I can control the speed better YMMV.

_________________

http://mckennaresonatorguitars.com/ |

|

|

|

Gregg McKenna

From:

South Windsor, Connecticut, USA

|

Posted 19 Feb 2011 6:32 pm

Posted 19 Feb 2011 6:32 pm |

|

| Mark Eaton wrote: |

Good to see Gregg chime in on this thread, and I'm guessing that he, Paul Beard, and Ivan Guernsey, whose guitars Mike Auldridge played for a number of years, didn't construct their early 8 strings out of thin air.

|

Actually, when I started building 8's, I only modified the same guitar style I was already building for 6's with a wider block inside the body (neck block) and a wider neck/larger headstock. The internal construction was plenty strong enough that it didn't need any alteration. My early 8's are the same as the ones I'm making now.

_________________

http://mckennaresonatorguitars.com/ |

|

|

|

William W Western

From:

Canada

|

Posted 19 Feb 2011 7:27 pm

Posted 19 Feb 2011 7:27 pm |

|

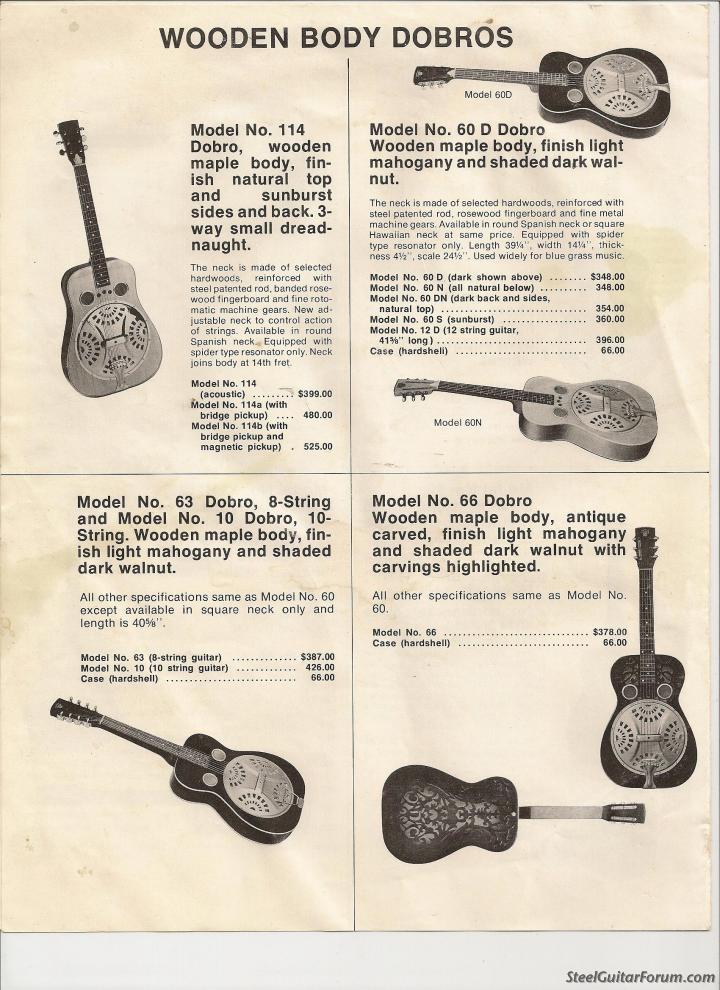

OMI brochure from about 1974.

| Quote: |

I had a dobro teacher in 1977 who liked the sound of my pre-war circa 1930 Dobro so much that he offered me an S-10 pedal steel and a newish at the time 8 string OMI Dobro in trade for it. So the 8 string resonator guitar concept has been around for quite a few years, and there were examples of the instrument built by the Dopyeras. |

|

|

|

|